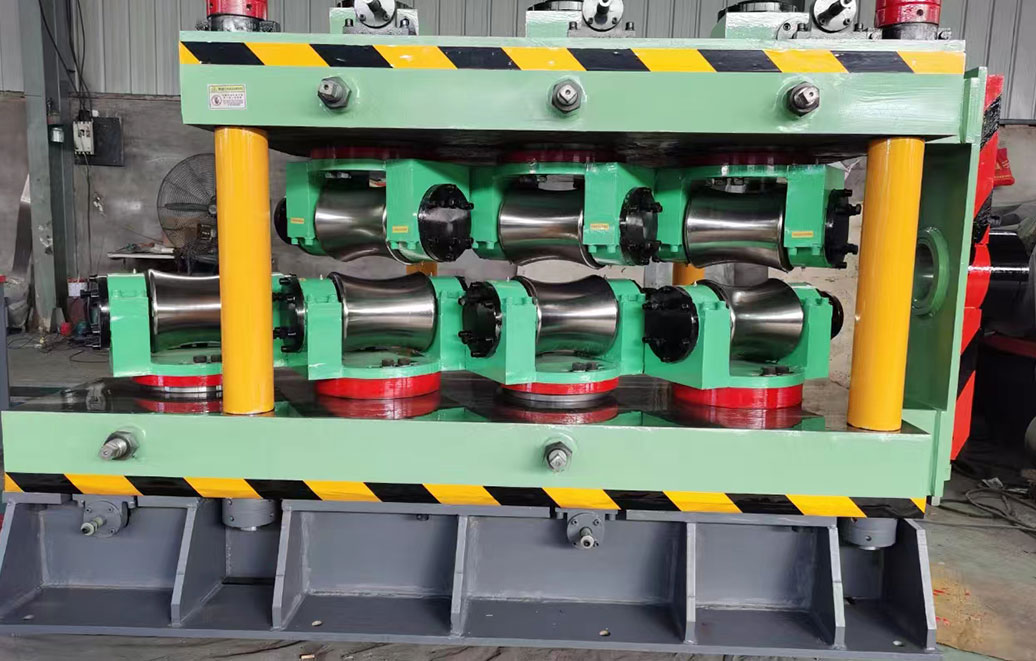

The scaffolding pipe straightening machine operates on a straightforward yet effective mechanism. Typically, the machine features a series of rollers and hydraulic presses that apply a uniform pressure on bent pipes. The operator feeds the bent pipe into the machine, which then automatically aligns and straightens it. Most machines are equipped with adjustable settings to accommodate various pipe sizes and materials.

- Technological Advancements Innovations in cold rolling technology can lead to enhanced efficiency and lower production costs. For example, mills equipped with advanced automation systems or cutting-edge roller technology can produce higher-quality products at a lower cost. However, these technological advancements often come with significant initial investments, which can also affect pricing.