Another significant benefit is the environmental impact of electric pipe making machines. By utilizing electric power, these machines produce fewer emissions compared to their gas-powered counterparts. This aspect aligns with the growing emphasis on sustainable manufacturing practices, where companies are increasingly looking to reduce their carbon footprint.

Moreover, customization is increasingly becoming a valuable proposition. Different industries may require specific types of pipes with unique dimensions, wall thicknesses, and finishes. A reputable manufacturer will offer tailored solutions to meet these diverse needs, allowing companies to optimize their production processes and enhance their product offerings. This adaptability is crucial in today’s fast-paced market where customer demands are continually evolving.

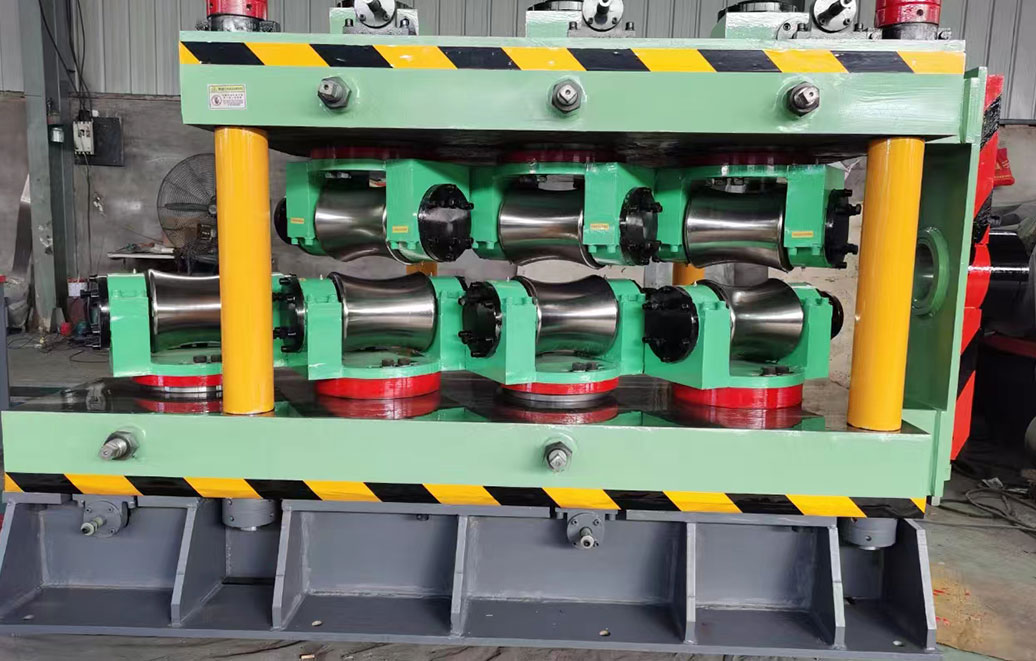

4. Technology and Features Modern square pipe making machines come equipped with advanced technologies such as Computer Numerical Control (CNC), programmable logic controllers (PLC), and monitoring systems. The inclusion of these features enhances precision and efficiency but also raises the overall price.