- Technological Advancements Innovations in cold rolling technology can lead to enhanced efficiency and lower production costs. For example, mills equipped with advanced automation systems or cutting-edge roller technology can produce higher-quality products at a lower cost. However, these technological advancements often come with significant initial investments, which can also affect pricing.

Shear shredders are versatile and can handle a wide range of materials, including plastic, rubber, metal, wood, and electronic waste. In recycling facilities, they are commonly used to process scrap metal, reducing it to manageable sizes for further recycling operations. In the plastics industry, shear shredders are employed to break down various plastic products and packaging, facilitating the recycling process and enabling the recovery of valuable materials.

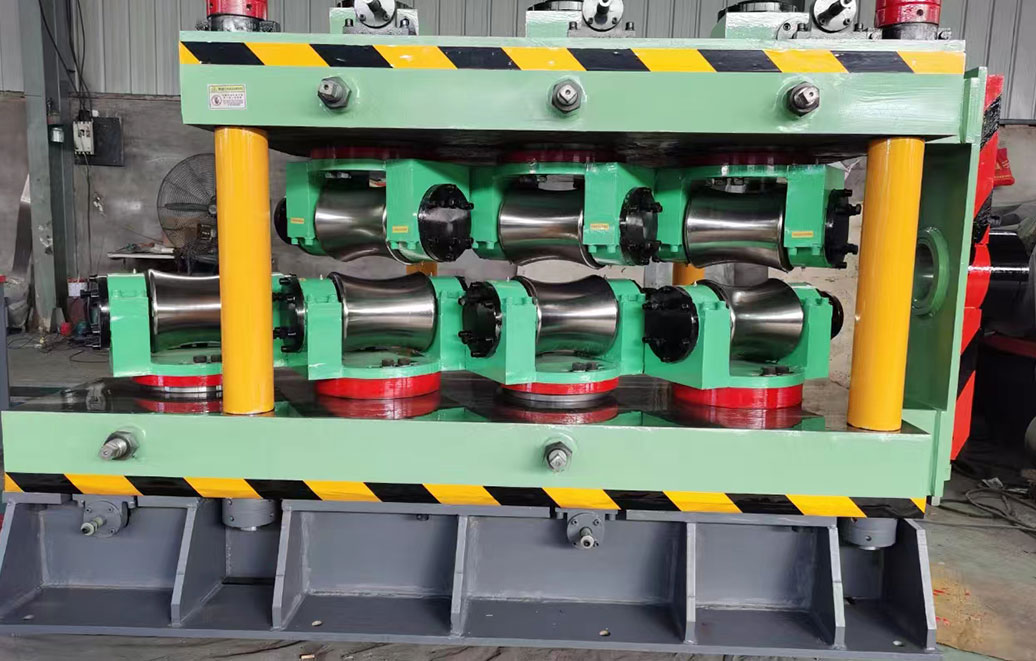

Roller straightening machines are particularly popular in industries dealing with larger and thicker sheets. These machines use two or more rollers to apply pressure along the length of the sheet, gradually reshaping it into a flat plane. This method is often preferred due to its ability to handle heavy materials without compromising their structural integrity. For thinner sheets, mechanical straighteners can provide a more precise solution, utilizing a system of controlled bends and pressure points to achieve the desired flatness.