Moreover, customization is increasingly becoming a valuable proposition. Different industries may require specific types of pipes with unique dimensions, wall thicknesses, and finishes. A reputable manufacturer will offer tailored solutions to meet these diverse needs, allowing companies to optimize their production processes and enhance their product offerings. This adaptability is crucial in today’s fast-paced market where customer demands are continually evolving.

In addition to recycling applications, shear shredders are increasingly used in waste-to-energy facilities. By shredding organic waste and other combustible materials, these machines prepare feedstock for conversion into energy. This not only helps in reducing the volume of waste sent to landfills but also contributes to sustainable energy production, showcasing the pivotal role shear shredders play in promoting a circular economy.

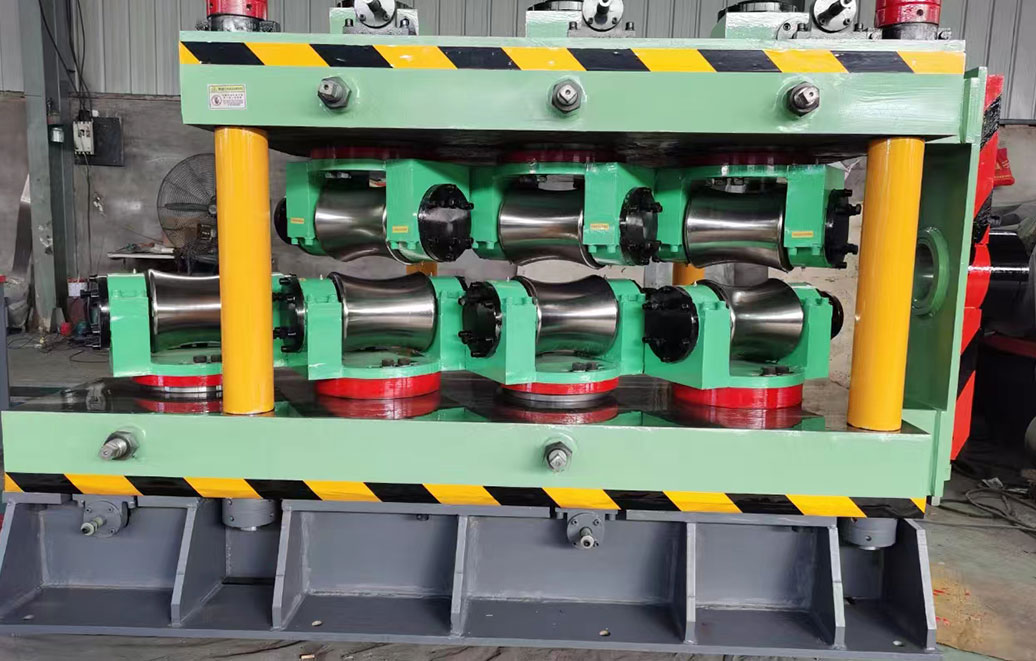

3. Versatility Modern pipe punching machines are designed to handle a variety of pipe sizes and materials, including steel, aluminum, and plastic. This versatility enables manufacturers to use a single piece of equipment for multiple projects, significantly reducing the need for specialized machines.