Additionally, the integration of advanced manufacturing techniques, such as 3D printing and precision machining, has allowed manufacturers to create complex, custom-fit pipe systems that minimize waste and enhance performance. These innovations not only improve the ecological footprint of manufacturing processes but also enable companies to rapidly respond to the dynamic needs of the market.

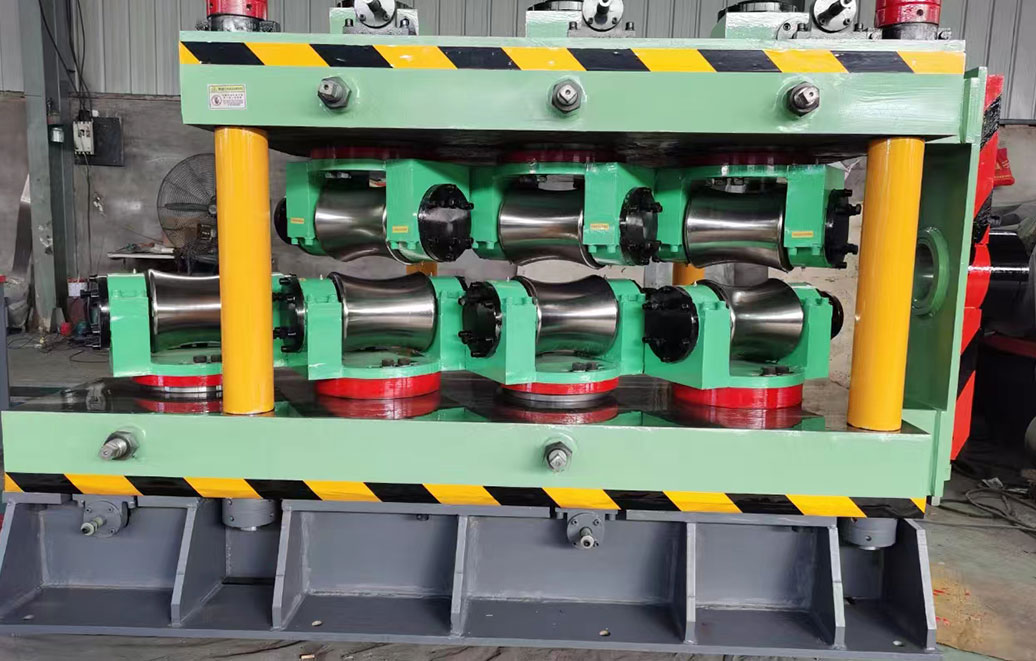

1. Technology and Features The level of technology incorporated into a straightening machine can significantly impact its price. Advanced features such as CNC (Computer Numerical Control) capabilities, automatic adjustments, and real-time monitoring systems may raise the cost. Machines equipped with state-of-the-art technology provide greater accuracy and efficiency but at a higher initial investment.