Moreover, customization is increasingly becoming a valuable proposition. Different industries may require specific types of pipes with unique dimensions, wall thicknesses, and finishes. A reputable manufacturer will offer tailored solutions to meet these diverse needs, allowing companies to optimize their production processes and enhance their product offerings. This adaptability is crucial in today’s fast-paced market where customer demands are continually evolving.

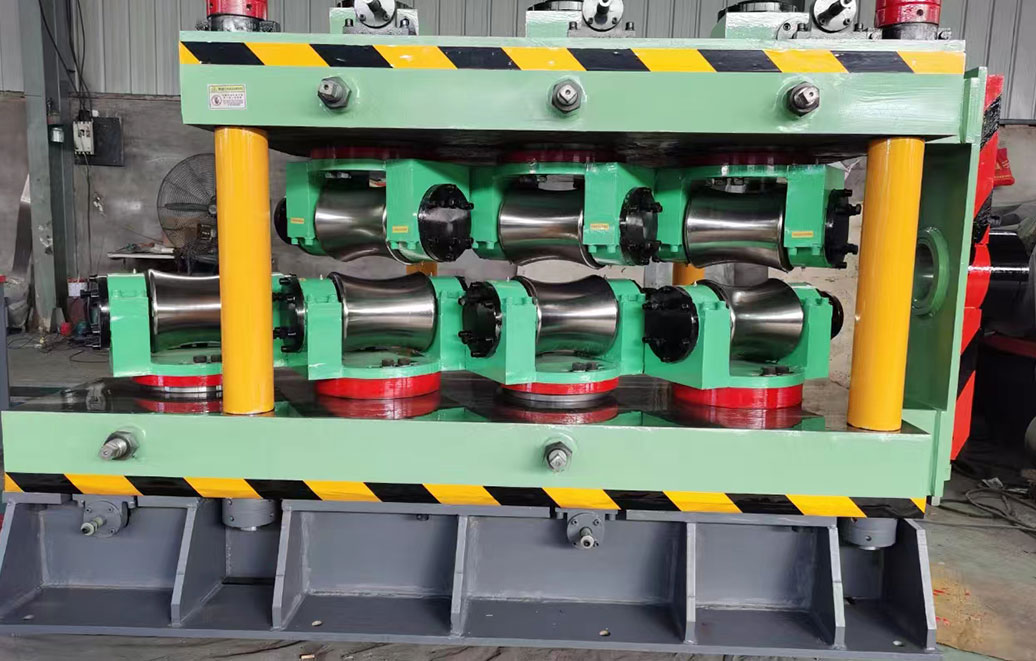

The operation of a small straightening machine is typically straightforward. Metal strips are fed into the machine, where they pass through a series of rollers and straightening tools. These components exert pressure on the metal to realign it, effectively eliminating any irregularities. The process is often automated, enabling faster production rates and reducing the chances of human error. As a result, manufacturers can increase their output without compromising on quality.