1. Technology and Features The level of technology incorporated into a straightening machine can significantly impact its price. Advanced features such as CNC (Computer Numerical Control) capabilities, automatic adjustments, and real-time monitoring systems may raise the cost. Machines equipped with state-of-the-art technology provide greater accuracy and efficiency but at a higher initial investment.

As the world increasingly focuses on sustainability, line pipe manufacturers are adapting their practices to minimize environmental impacts

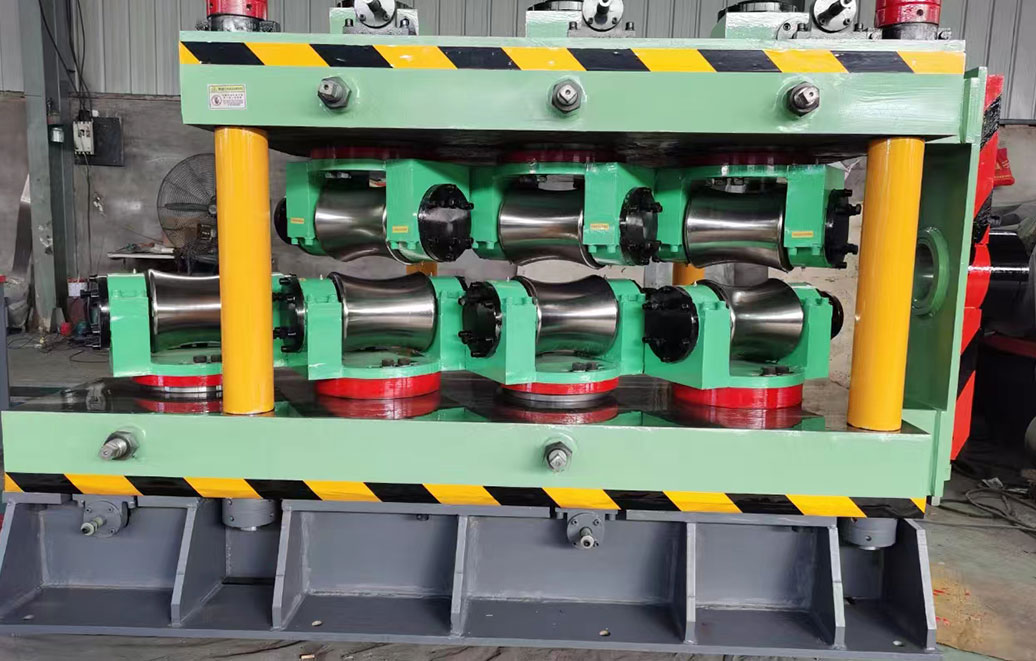

. Many organizations are investing in technologies that reduce emissions during manufacturing processes and are also exploring the use of recycled materials in their products. Additionally, the development of bioplastics presents a promising alternative for certain applications, particularly in the water supply sector.3. Automatic Wire Straightening Machines Fully automated machines provide optimal efficiency and precision in high-volume production settings. They usually come equipped with advanced features such as digital controls, sensors, and programmable settings to accommodate various wire types and sizes.