Brake machines, also known as press brakes, are vital for bending and shaping metal sheets. They utilize a combination of vertical pressure and a specific die to create bends at predefined angles. The versatility of brake machines allows for the production of complex shapes, making them indispensable in industries such as automotive, aerospace, and construction.

Moreover, customization is increasingly becoming a valuable proposition. Different industries may require specific types of pipes with unique dimensions, wall thicknesses, and finishes. A reputable manufacturer will offer tailored solutions to meet these diverse needs, allowing companies to optimize their production processes and enhance their product offerings. This adaptability is crucial in today’s fast-paced market where customer demands are continually evolving.

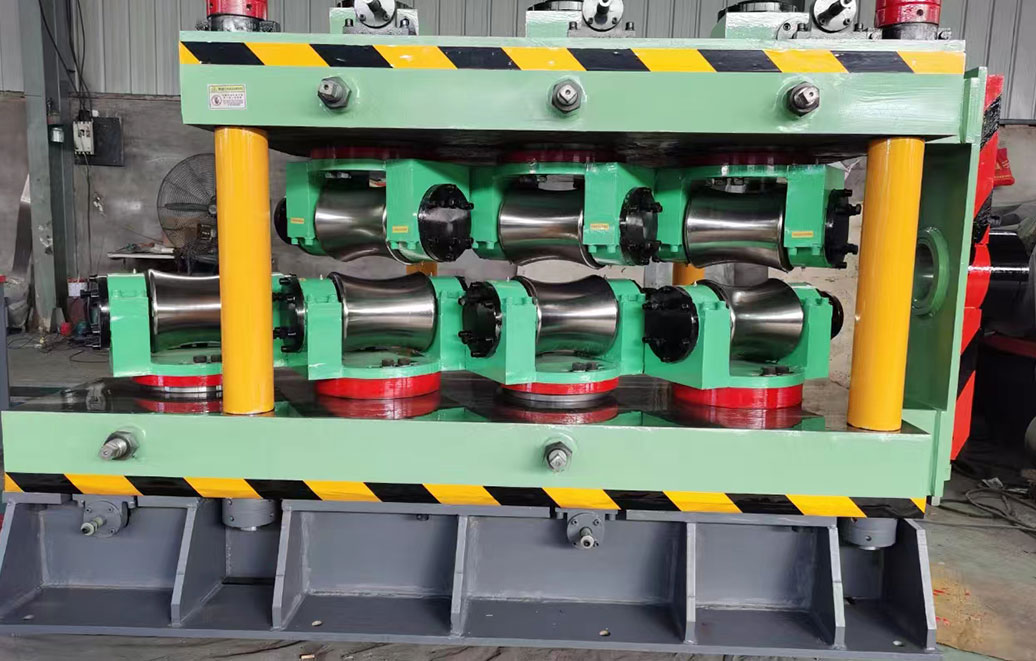

The versatility of rollforming machines is one of their standout features. They can produce a wide range of profiles, from simple U-channels to complex shapes like Z-purlins and C-sections. This versatility is essential for the construction industry, where various steel components are required for different structural elements. Moreover, rollforming is not limited to steel alone; other metals like aluminum can also be processed, making these machines valuable across multiple sectors.