Flying Saw Factory Solutions for Industrial Cutting Needs

In modern manufacturing, efficiency and precision are two non-negotiable factors that determine competitiveness. A ໂຮງງານຜະລິດເລື່ອຍບິນ plays a vital role in meeting these demands by offering advanced equipment designed for continuous and accurate cutting processes. With decades of engineering innovation and specialized expertise, factories dedicated to producing flying saws have become crucial partners for industries such as steel pipes, welded tubes, and structural materials. These cutting solutions are engineered to synchronize with production lines, ensuring seamless cutting without halting operations, which greatly enhances productivity and reduces material waste.

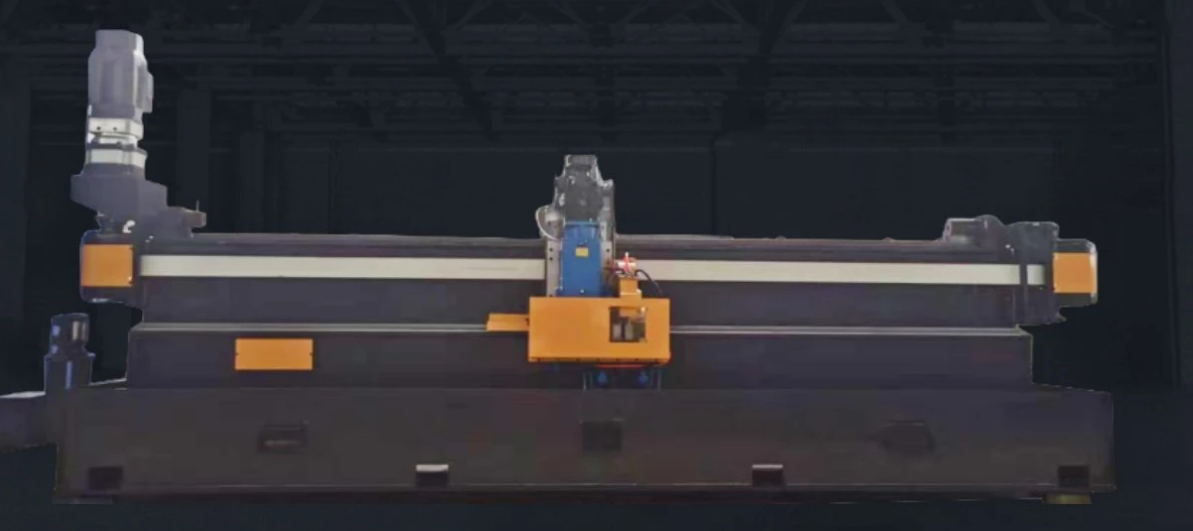

Innovation and Design Excellence in Flying Saw Manufacturing

The foundation of any ໂຮງງານຜະລິດເລື່ອຍບິນ is its design capability, where innovation meets real-world industrial requirements. Leading factories focus on creating machines that integrate mechanical precision, electrical synchronization, and intelligent control systems. For instance, cold cutting flying saws are designed to deliver burr-free and smooth cuts, which are essential for maintaining the integrity of welded pipes and steel tubes. By integrating servo-driven technology and digital control, these saws achieve high cutting speeds while ensuring precise dimensions. A strong design focus not only enhances operational efficiency but also reduces downtime, as the machines are built to handle continuous production without frequent adjustments.

Comprehensive Range of Flying Saw Equipment

A well-established ໂຮງງານຜະລິດເລື່ອຍບິນ does not limit itself to a single type of cutting machine. Instead, it provides a wide variety of solutions tailored to different industrial needs. From hot saws to cold cutting flying saws, each machine is engineered for specific applications, whether for thick-walled tubes, thin-walled pipes, or structural profiles. Many factories also design auxiliary equipment such as straightening machines, feeding systems, balers, and roller molds, creating a complete production ecosystem. This comprehensive approach ensures that customers can source all necessary cutting and supporting machinery from a single reliable manufacturer, simplifying procurement and technical coordination.

Quality Assurance and Manufacturing Expertise

When investing in heavy-duty industrial equipment, reliability and durability are paramount. A reputable ໂຮງງານຜະລິດເລື່ອຍບິນ emphasizes strict quality control at every stage of production. From material selection to machining accuracy and final assembly, each process is carefully monitored to meet international standards. Modern factories utilize CNC machining centers, precision grinding, and advanced heat treatment to produce high-performance components. These measures guarantee that flying saws can withstand long-term operation under demanding conditions. Furthermore, experienced engineers oversee the entire manufacturing cycle, ensuring that each unit is tested for performance, stability, and safety before delivery. This combination of expertise and rigorous inspection has positioned such factories as trusted partners in the global manufacturing supply chain.

Customization and Global Market Service

No two production lines are exactly the same, and a customer-oriented ໂຮງງານຜະລິດເລື່ອຍບິນ recognizes the importance of tailored solutions. Manufacturers often provide customized designs based on client requirements, including cutting diameter, wall thickness, speed, and automation level. By adapting technology to the specific needs of customers, these factories help maximize efficiency and ensure compatibility with existing production systems. Beyond the domestic market, many leading companies also serve international clients, offering installation guidance, after-sales training, and technical support. This global outlook not only strengthens their reputation but also contributes to the advancement of cutting technology worldwide.

Flying Saw Factory FAQs

What is a flying saw and how does it work?

A flying saw is a specialized cutting machine used in continuous production lines, particularly for pipes, tubes, and profiles. It works by synchronizing the movement of the saw with the material being processed, allowing the cut to be made without stopping the line. This ensures higher efficiency and smooth cutting surfaces.

What industries typically use equipment from a flying saw factory?

Industries such as steel manufacturing, welded pipe production, aluminum profiles, and structural tube fabrication are the primary users of flying saws. These machines are essential in sectors that demand high-speed, precise, and continuous cutting processes.

What is the difference between a hot saw and a cold cutting flying saw?

A hot saw uses thermal energy during the cutting process and is generally used for thicker or harder materials, but it may leave rougher edges. A cold cutting flying saw, on the other hand, uses mechanical blades and advanced servo systems to achieve smoother, burr-free cuts, making it ideal for welded pipes and precision applications.

How does a flying saw factory ensure quality in its machines?

Quality assurance is maintained through advanced CNC machining, precision assembly, heat treatment, and strict inspection procedures. Each machine undergoes rigorous testing for accuracy, durability, and stability before being delivered to the customer, ensuring long-term reliability in demanding production environments.

Can flying saw factories provide customized solutions?

Yes, most reputable flying saw factories offer customization services to meet specific production needs. They adjust machine design based on pipe diameter, thickness, cutting speed, and integration requirements, ensuring that the solution perfectly matches the customer’s production line.

-

Precision Cutting Machinery: From Low-Speed Saws to Advanced Flying Shearsຂ່າວAug.26,2025

-

Machinery for Pipe Fabrication: From Welding to Cuttingຂ່າວAug.26,2025

-

Leading Manufacturers of Pipe and Tube Machineryຂ່າວAug.26,2025

-

Key Manufacturers of Tube and Pipe Processing Machineryຂ່າວAug.26,2025

-

Best Machinery for Metal Pipe Fabrication: Cutting, Rolling, and Weldingຂ່າວAug.26,2025

-

Advanced Cutting Solutions: Exploring CNC Cold Saws and Flying Saws for Industrial Needsຂ່າວAug.26,2025