Tube Straightening Machine Working Principle & Advantages Efficient Scaffold Tube Straightening Solutions

- Introduction: The tube straightening machine working principle

and its relevance in modern industry - Understanding Mechanical Straightening and Key Factors

- Decoiler Machine Operations and Their Synergy with Straightening

- Technical Advantages and Performance Benchmarks

- Leading Manufacturers: Comparative Data and Analysis

- Customizing Solutions for Diverse Industrial Applications

- Conclusion: Maximizing Value via Scaffold Tube Straightening Machine Technology

(tube straightening machine working principle)

Introduction to Tube Straightening Machine Working Principle

The tube straightening machine working principle is essential to achieving tight dimensional tolerances in tube production and refurbishment. The process utilizes a succession of precision-aligned rollers to remove curvature defects and ensure that tubes meet straightness requirements set by international standards, such as ASTM and EN. In today's high-speed manufacturing, including sectors like automotive, construction, and aerospace, a deviation in tube straightness greater than 1 mm/meter can result in assembly inefficiencies and structural instabilities. With precision demands now reaching ±0.2 mm/meter, understanding how straightening systems function is crucial for manufacturers and end-users aiming for quality assurance, reduced waste, and increased throughput.

Mechanical Straightening: Principles, Rollers, and Adjustment Variables

The fundamental tube straightening machine working principle relies on a series of individually adjustable rollers, typically arranged in an alternating concave-convex pattern across two opposite planes. Tubes are passed through this roller bank, where targeted plastic deformation corrects both horizontal and vertical bends caused by upstream handling or fabrication processes, such as welding or cutting.

Key parameters influencing straightening efficacy include:

- Roller Gap: The distance between upper and lower rollers, which must be precisely adjusted for tube diameter and wall thickness.

- Feed Speed: Higher speeds may increase productivity but risk inadequate straightening or surface damage.

- Applied Force Distribution: The sequence and magnitude of force applied by the rollers greatly affect the outcome, with optimal results achieved by balancing force to avoid tube collapse or springback.

Decoiler Machine Working and Integration with Straightening Lines

Efficient tube processing frequently begins with decoiler machine working in tandem with a straightening unit. Decoilers are responsible for feeding raw tube coils or pipes into the downstream modules, maintaining tension and alignment to prevent material deformation before straightening. They are often equipped with automatic braking and centering systems to synchronize with the straightener's feed rate.

Synergistic operation ensures smooth transitions from coiled stock to precisely aligned tubes, minimizing bottlenecks and surface imperfections. In fully integrated lines, programmable logic controllers (PLCs) allow for seamless communication, ensuring the decoiler adjusts uncoiling force and speed according to the straightener's operational load. Downtime reduction is another benefit—plants report up to 35% higher throughput when decoilers and straighteners are optimally paired compared to older, manually coordinated setups.

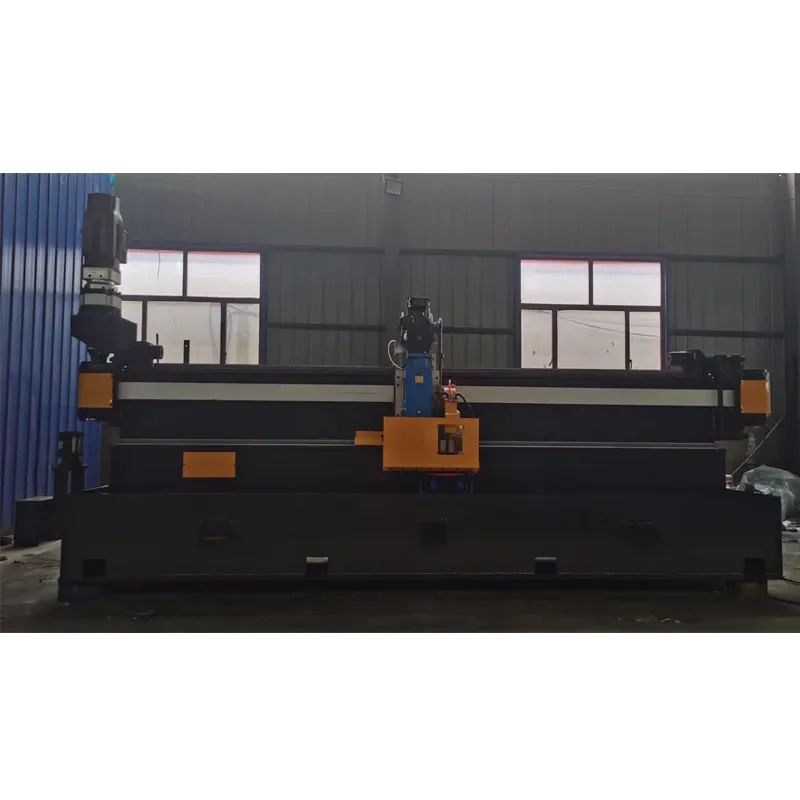

Technical Advantages: Scaffold Tube Straightening Machine Performance

Across a range of applications, scaffold tube straightening machines demonstrate unique technical advantages. For instance, modern six-roller straighteners achieve straightness deviations below 0.15mm/meter at speeds up to 60 meters per minute on 48.3/60.3mm OD tubes—standard sizes in scaffolding.

Other notable technical benefits:

- Automated Error Compensation: Sensors detect and adjust for material inconsistencies in real time.

- Energy Efficiency: Servo-driven roller systems deliver up to 20% reductions in power consumption compared to legacy hydraulic machines.

- Surface Integrity: Roller surface hardening and micro-polishing prevent indentation or surface cracks, extending tube lifespan.

Manufacturer Comparison: Data-Driven Evaluation Table

Evaluating tube straightening machine vendors requires consideration of output quality, speed, after-sales support, and customization ability. The following comparative table summarizes the key specifications and performance benchmarks of prominent manufacturers:

| Manufacturer | Model | Roller Sets | Tube Diameter Range (mm) | Max Speed (m/min) | Straightness Accuracy (mm/m) | Energy Consumption (kWh) | After-Sales Support |

|---|---|---|---|---|---|---|---|

| BUEHLER | STR-60X | 7 | 12–76 | 55 | 0.12 | 5.8 | 24/7 Global |

| Hitech Rollers | HTR-S48 | 6 | 20–60 | 60 | 0.15 | 4.9 | Asia, Europe |

| Yoder Machinery | YT-STR84 | 8 | 16–89 | 52 | 0.10 | 6.2 | North America |

| Eagle Group | EGL-STRAIGHTER | 5 | 25–100 | 40 | 0.22 | 5.5 | Global |

As evidenced above, Hitech Rollers sets the benchmark for production speed on scaffold tubing, while Yoder Machinery leads in accuracy. The decision matrix should weigh throughput, availability of technical personnel, and long-term operating costs, which can differ by up to $9,000 annually depending on energy requirements.

Custom Solutions: Tailoring Tube Straightening for Industry-Specific Demands

Not all operations can be fulfilled by off-the-shelf machines. Manufacturing environments frequently require customizations, such as:

- Variable roller configurations to handle non-standard tube geometries (e.g., elliptical, square, or thick-walled pipes).

- Integration with robotic handling systems for fully automated production lines.

- Low-noise and vibration-dampening features for cleanroom or precision manufacturing sectors.

Providers offer modular approaches where decoiler machine working, straightening, and end-facing units can be flexibly combined. This tailored engineering ensures optimal fit—both physically and operationally—with client layouts, including space constraints and expansion prospects.

Conclusion: Enhancing Efficiency with Scaffold Tube Straightening Machine Advancements

Investing in a modern scaffold tube straightening machine, built on the refined tube straightening machine working principle and synergized with decoiler machine working systems, translates directly into improved yield, safety, and profitability across a range of industries. Case studies from leading infrastructure projects illustrate real-world benefits: in one large-scale metro construction, a shift to next-generation straightening lines increased daily scaffold tube output by 27% and cut rework costs by nearly $200,000 in a single fiscal year.

The ongoing evolution of roller configurations, automation, and software intelligence means that businesses can expect even greater returns from future upgrades. Whether retrofitting legacy lines or specifying greenfield installations, a strategic focus on straightening technology remains critical for operational excellence in the era of smart manufacturing.

(tube straightening machine working principle)

FAQS on tube straightening machine working principle

Q: What is the working principle of a tube straightening machine?

A: A tube straightening machine works by passing bent or curved tubes through a series of rollers that apply pressure and gradually straighten them. The rollers are adjustable to accommodate different diameters and degrees of curvature. This process improves the tube's straightness for further processing.Q: How does a decoiler machine work in a production line?

A: A decoiler machine feeds coiled raw material into the production line by uncoiling and straightening it as needed. It ensures a smooth and consistent supply of material for processing machines such as tube straighteners. The decoiler’s speed and tension can be controlled to match the requirements of the downstream equipment.Q: What makes a scaffold tube straightening machine different from regular tube straightening machines?

A: A scaffold tube straightening machine is specifically designed to handle the larger diameters and heavier weights of scaffold tubes. It uses robust rollers and higher pressure to accommodate thick, heavy-duty pipes. This ensures scaffold tubes are straightened efficiently for safe use in construction.Q: Can tube straightening machines handle different tube sizes?

A: Yes, tube straightening machines generally have adjustable rollers to accommodate various tube diameters and wall thicknesses. This allows for versatile operation across a range of tube specifications. Proper adjustment ensures maximum straightening efficiency and product quality.Q: Why is tube straightening important in manufacturing?

A: Tube straightening ensures that pipes and tubes have the required precision and structural integrity for their end-use applications. Straight tubes are vital for seamless assembly and aesthetic quality in industries like automotive, construction, and furniture. The process also helps reduce material waste and improve production efficiency.-

Best Piping Cutting Machine Price Automatic & Wire Straightening Cutting Machine CostNewsJun.24,2025

-

Top Straightening Machine Supplier – High Precision Solutions for Metal ProcessingNewsJun.10,2025

-

High Efficiency Rotary Shear Machine for Precision Cutting Versatile Rotary Shear Shredder & Cordless OptionsNewsJun.10,2025

-

High-Precision Cold Rolled Steel Machine for Quality ProductionNewsJun.09,2025

-

Metal Tube Making Machine – High Precision & AutomationNewsJun.09,2025