High Efficiency Stainless Steel Tube Making Machine Leading Tube Mill Manufacturer

- Introduction to the stainless steel tube making machine

market - Global trends and market data: The growing demand for stainless steel tubes

- Key technical advantages of modern stainless steel tube mill machines

- Comparative analysis of leading stainless steel pipe making machine manufacturers

- Customization strategies for optimal tube production solutions

- Successful application cases across diverse industries

- Conclusion and future prospects for stainless steel tube making machines

(stainless steel tube making machine)

Introduction: Shaping the Industry with Stainless Steel Tube Making Machine Solutions

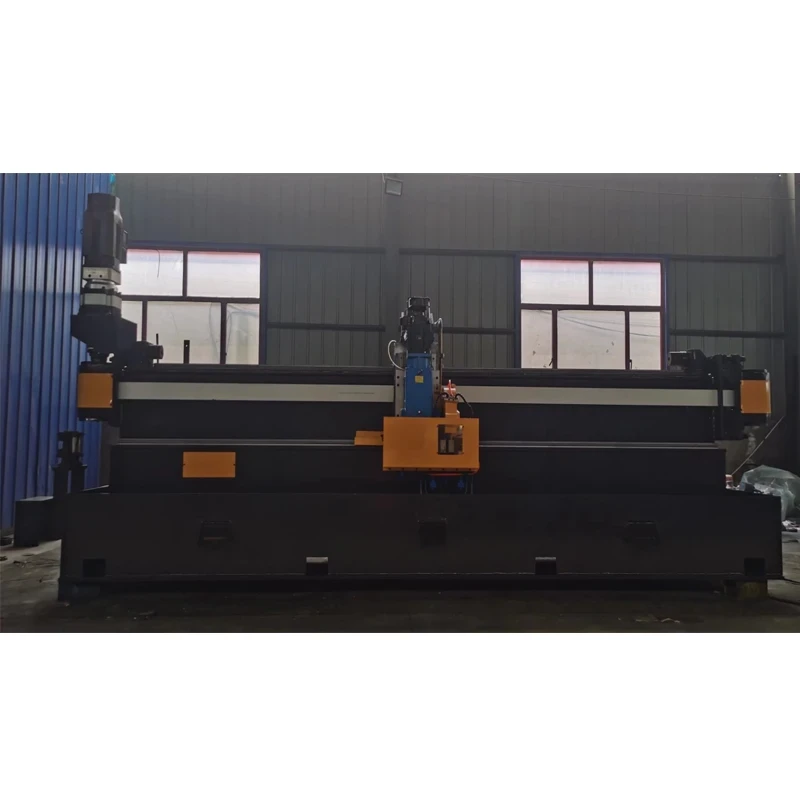

In today's fast-evolving manufacturing landscape, the stainless steel tube making machine sector stands as a cornerstone for diverse industries. These machines are engineered to deliver high-precision, corrosion-resistant tubing essential for critical sectors including construction, automotive, energy, and healthcare. As infrastructure projects expand globally, the demand for seamless and durable stainless steel tubes continues to surge. Stainless steel tube mill machines are designed for maximum efficiency, reduced wastage, and consistent output quality. The transition from manual fabrication to automated tube forming systems has radically improved plant productivity, minimized human error, and enabled scalable operations.

With expectations for global stainless steel consumption to exceed 52 million metric tons in 2024, manufacturers are under increasing pressure to embrace automated solutions. Investing in advanced stainless steel pipe making machines ensures not only superior tube quality but also energy and cost savings in the long term. This introduction sets the stage for exploring technical advancements, market dynamics, and industry benchmarks that guide today’s procurement decisions.

Global Market Dynamics and Surging Stainless Steel Tube Demand

The stainless steel tube market, valued at approximately USD 30.5 billion in 2023, is projected to grow at a CAGR of 6.2% from 2024 to 2030. Power generation, shipbuilding, fluid transport, and food processing are among the primary demand drivers. The proliferation of eco-friendly technologies and infrastructure modernization, particularly in emerging economies, further accelerates this trend.

Data reveals that Asia-Pacific leads global stainless steel tube consumption, accounting for over 55% of worldwide demand. This is closely followed by Europe and North America, where ongoing investments in green buildings and medical facilities maintain consistent market growth.

The largest stakeholders—manufacturers of stainless steel tube mill machines—have implemented smarter production lines, real-time monitoring systems, and predictive maintenance. As a result, production downtime in top factories has been reduced by up to 27%, according to industry surveys.

Technical Superiority: What Sets Modern Tube Mill Machines Apart?

Modern stainless steel pipe making machines are engineered with high-grade metallurgy and precision automation to meet rigorous industry standards. The adoption of servo motor drives, PLC-controlled operations, and intelligent welding technologies has set new industry benchmarks for speed and quality. Line speeds upwards of 120 meters per minute are now standard in high-performance models.

Innovations such as internal bead rolling, eddy current testing, and automated laser alignment enable manufacturers to achieve dimensional accuracy of ±0.03 mm—critical for sectors like medical tubing and automotive fuel lines. Energy-efficient induction welding, instead of traditional TIG or MIG, significantly lowers operational costs and reduces heat distortion on thin-walled tubes.

Table 1 presents a snapshot comparison of key technical specifications from leading tube mill machine manufacturers:

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Tube Diameter Range | 6 mm – 50 mm | 8 mm – 76 mm | 10 mm – 63 mm |

| Line Speed | 90 m/min | 120 m/min | 80 m/min |

| Welding Technology | Induction Welding | TIG/Induction | Laser/TIG Hybrid |

| Automation Level | PLC + Servo Motor | Full Smart Line | PLC |

| Accuracy (mm) | ±0.05 | ±0.03 | ±0.04 |

| Energy Consumption | 5.4 kWh/m | 4.9 kWh/m | 5.7 kWh/m |

The improvement in automation, energy efficiency, and weld quality significantly reduces scrap rates, increases throughput, and ensures reliable long-term operation.

Manufacturer Benchmarks: Comparing Stainless Steel Pipe Making Machine Providers

Choosing the right stainless steel pipe making machine manufacturer is critical for successful tube production. Leading brands emphasize innovation, after-sales service, and global certifications such as CE, ISO9001, and ASME compliance.

Manufacturer A, renowned for rugged chassis and modular design, is favored by factories requiring frequent line changes. Manufacturer B’s smart integration platform supports Industry 4.0 compatibility, providing advanced data analytics and remote diagnostics. Manufacturer C occupies a competitive niche with its hybrid laser welding capabilities, targeting precision-critical sectors.

The after-sales ecosystem, technical training support, and availability of spare parts directly affect machine uptime. According to a recent OEM customer survey, 78% of buyers consider lifecycle support and automation upgrades as key determinants in selecting their equipment partner.

| Feature | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Certifications | ISO9001, CE | ISO9001, CE, ASME | CE |

| Warranty | 2 Years | 3 Years | 2 Years |

| After-Sales Network | Asia, Europe | Global | Asia, North America |

| User Training | Onsite & Remote | Onsite | Online |

| Spare Parts Availability | 24-48 hours | 48-72 hours | Same week |

Large-scale buyers often leverage supplier partnership programs for exclusive discounts, early access to technical updates, and custom engineering support.

Customization in Stainless Steel Tube Mill Machines: Tailoring to Production Needs

The growing diversity of industrial applications necessitates flexible customization of stainless steel tube making machines. Top manufacturers offer modular designs, allowing swift wheel and roller changes, scalable entry systems, and adjustable forming stations to accommodate a wide spectrum of tube diameters and thicknesses.

Customization parameters include:

- Tube shape and profile: Round, square, rectangular, oval, and bespoke geometries

- Material handling: Automated coil loading, decoiler integration, and inline straighteners

- Surface finish options: Bright annealed, satin, mirror polish, bead-removed

- Inline NDT systems: Automated ultrasonic, eddy current, or X-ray testing for quality assurance

- Software capabilities: Real-time SCADA interfaces, historical data tracking, and preventive maintenance scheduling

An efficient custom configuration directly translates to reduced downtime, higher output, and the ability to pivot to new product lines as market demands evolve.

Real-World Application Success: Industry Case Studies

The integration of advanced stainless steel tube mill machines brings transformative results across various sectors. For example, a European automotive supplier leveraged a new servo-driven tube forming line to increase its monthly output by 34%, meeting a surge in demand for electric vehicle battery cooling tubes.

In the pharmaceutical industry, a leading contract manufacturer adopted a fully automated stainless steel pipe making machine, achieving zero cross-contamination incidents over a 12-month period due to superior internal bead removal and automated cleaning cycles.

A construction conglomerate in Southeast Asia transitioned from manual welding to AI-driven tube mill machines, reducing labor costs by 28% and tube rejection rates from 4.1% to just 0.8%. These case studies exemplify the substantial operational advantages achievable through intelligent equipment upgrades.

Conclusion: Trusting the Future of Production to Stainless Steel Tube Making Machine Technologies

The stainless steel tube making machine market will continue evolving as manufacturers adopt smart automation, sustainable practices, and advanced material processing techniques. Strategic investment in stainless steel tube mill machines is a proven pathway to enhanced productivity, reduced waste, and long-term business growth.

When selecting a stainless steel pipe making machine manufacturer, businesses benefit from a holistic approach—balancing technical innovation, lifecycle support, and tailored solutions. As industry demands shift toward even greater precision and efficiency, only those who embrace the latest tube forming technologies will maintain their leadership in an increasingly competitive global market.

(stainless steel tube making machine)

FAQS on stainless steel tube making machine

Q: What is a stainless steel tube making machine?

A: A stainless steel tube making machine is equipment designed to manufacture stainless steel pipes and tubes from flat strips. It can form, weld, and size the tubes in a continuous process. This machine is vital in industries requiring corrosion-resistant tubing.Q: How does a stainless steel tube mill machine work?

A: A stainless steel tube mill machine forms steel strips into circular shapes, welds the edges, and sizes the tube. It uses rollers, welding units, and sizing mechanisms. The result is a finished stainless steel pipe ready for various industrial uses.Q: What should I consider when choosing a stainless steel pipe making machine manufacturer?

A: Look for manufacturers with a strong reputation for quality, reliable after-sales service, and industry certifications. Customer support and customization options are also important. Always compare technical specifications to meet your production needs.Q: What are the main benefits of using a stainless steel tube making machine?

A: The main benefits include increased production efficiency, consistent tube quality, and reduced labor costs. It also allows for precision manufacturing of various tube sizes and thicknesses. These machines are essential for high-volume pipe production.Q: Can a stainless steel tube mill machine produce different pipe shapes and sizes?

A: Yes, most stainless steel tube mill machines can be adjusted to produce various pipe diameters and wall thicknesses. Some models can even make square or rectangular pipes. This versatility suits diverse industry requirements.-

Advanced Industrial Solutions-Example Company|Smart Manufacturing Platforms&Sustainable Production SolutionsNewsJul.13,2025

-

Industrial Solution-[Company Name]|Production Efficiency&Cost ManagementNewsJul.13,2025

-

Industrial Automation Solutions-Example Corp|Operational Efficiency&Cost ReductionNewsJul.13,2025

-

Industrial Solutions-InnovateTech Solutions|Efficiency&Cost-EffectivenessNewsJul.12,2025

-

High-Precision Bend Punch Shear Machines Efficient Hydraulic Punch and Shear SolutionsNewsJul.08,2025