Precision and Material Integrity in Cold Cutting Flying Saw Applications

In industries where dimensional accuracy and material preservation are paramount, cold cutting technologies like the sharrë e prerë fluturuese, flying saw, dhe sharrë e ftohtë me shpejtësi të lartë have become indispensable. These systems eliminate thermal distortion, ensuring clean cuts while maintaining the structural integrity of metals and alloys. The growing demand for lightweight, corrosion-resistant materials in aerospace, automotive, and renewable energy sectors has further amplified the need for precision cold cutting solutions. This article explores their design principles, material-specific applications, and answers common questions about their industrial use.

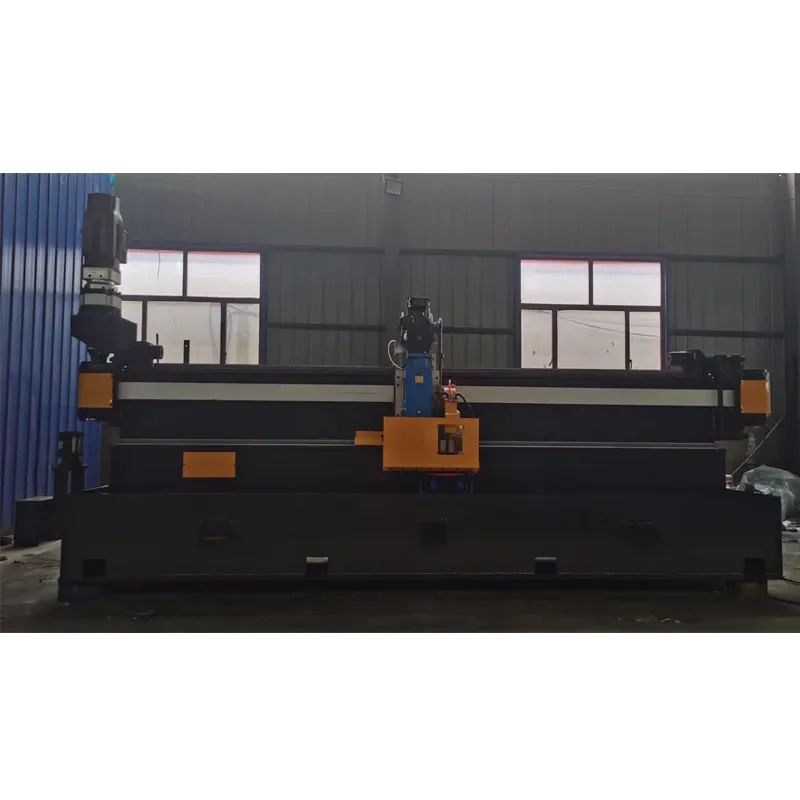

Flying Cut Off Saw: Principles of Cold Cutting

Të sharrë e prerë fluturuese operates by synchronizing its blade speed with moving material, executing precise cuts without halting production lines. Unlike thermal methods, cold cutting avoids heat-affected zones (HAZs), making it ideal for temperature-sensitive metals like stainless steel, aluminum, and titanium. In aerospace manufacturing, these saws cut titanium landing gear components, preserving fatigue resistance by preventing microstructural changes. Titanium’s susceptibility to oxygen embrittlement at high temperatures makes cold cutting critical for maintaining its mechanical properties.

Advanced models use carbide-tipped blades with variable tooth geometries to adapt to material hardness. For example, fine-tooth blades cleanly slice thin-walled aluminum tubes for HVAC systems, while coarse teeth handle thick carbon steel beams in construction. Automated lubrication systems further reduce friction, extending blade life when processing abrasive materials like fiberglass-reinforced polymers. In semiconductor manufacturing, these saws cut copper heat sinks with burr-free edges to ensure optimal thermal contact with microchips.

Another breakthrough is the integration of vibration-dampening systems. When cutting brittle materials like cast iron, blade oscillations can cause micro-cracks. Modern flying cut off saws employ active damping mechanisms, using piezoelectric sensors to counteract vibrations in real time. This is particularly vital for automotive brake rotor production, where surface integrity directly impacts safety.

Flying Saw: Synchronization and Accuracy

A flying saw achieves millimeter-level precision through servo-driven synchronization with conveyor systems. This technology is critical for high-speed production of pipes, extrusions, and profiles. In automotive assembly lines, flying saws cut aluminum chassis components to exact lengths, ensuring seamless robotic welding downstream. The transition to electric vehicles (EVs) has intensified demand for precision-cut battery tray components, where even minor dimensional errors can compromise crash safety.

Material versatility is a hallmark of modern flying saw systems. For copper-nickel alloys used in desalination plants, non-sparking blades prevent ignition risks, while diamond-coated blades handle ceramic-coated steel pipes in chemical processing. Real-time feedback loops adjust blade descent rates based on material density, preventing deformation in soft metals like brass. In architectural applications, these saws cut decorative bronze cladding panels, maintaining intricate patterns without edge tearing.

Recent advancements include AI-powered predictive maintenance. By analyzing blade wear patterns and motor performance data, flying saw systems can schedule blade replacements before failures occur. This reduces downtime in high-volume industries like steel service centers, where continuous operation is essential.

Flying Cut Off Machine: Versatility Across Materials

Të makine fluturuese prerëse combines mobility with robust cutting power, serving industries from metal fabrication to renewable energy. These machines excel in processing mixed-material batches, such as carbon steel beams paired with PVC-coated electrical conduits. In shipbuilding, they section stainless steel hull pipes without compromising corrosion-resistant surfaces. The ability to switch between materials like Inconel for exhaust stacks and galvanized steel for structural frames makes these machines indispensable in maritime applications.

Blade cooling systems are tailored to material needs. For instance, water-cooled blades prevent work hardening when cutting nickel-based superalloys for turbine blades, while dry-cutting configurations maintain cleanliness for food-grade stainless steel tubing. Modular designs allow quick swaps between circular blades for metals and abrasive discs for composites. In wind turbine manufacturing, makina fluturuese prerëse prepare fiberglass-reinforced polymer (FRP) blades, ensuring smooth edges to avoid stress concentrations during operation.

Emerging applications include the recycling industry, where makina fluturuese prerëse dismantle hybrid material assemblies. For example, separating aluminum frames from lithium-ion battery packs in EV recycling requires precise cuts to avoid short circuits or toxic leaks.

High Speed Cold Saw: Efficiency Without Compromise

Të sharrë e ftohtë me shpejtësi të lartë delivers rapid cuts while maintaining cold working advantages. Operating at RPMs exceeding 3,000, these saws handle high-volume tasks like slicing titanium rods for medical implants or aluminum extrusions for window frames. Precision-ground blades produce burr-free edges, eliminating secondary grinding in electronics component manufacturing. For smartphone chassis made from magnesium alloys, sharra të ftohta me shpejtësi të lartë achieve mirror-finish cuts that meet aesthetic and functional requirements.

Material-specific blade coatings enhance performance. Titanium nitride-coated blades extend longevity when cutting hardened steel gears, while polymer-friendly blades prevent delamination in carbon-fiber-reinforced plastics (CFRP). In renewable energy, these saws prepare wind turbine mast sections from weather-resistant steel alloys, ensuring tight tolerances for assembly. Offshore wind farms rely on corrosion-resistant duplex stainless steel components cut with minimal kerf loss to maximize material utilization.

Innovations in blade geometry, such as variable helix angles, reduce cutting forces when processing laminated materials. This is critical for aerospace composites like CFRP-aluminum hybrids, where delamination could compromise structural integrity.

FAQS:About High Speed Cold Saw Applications

How does a flying cut off saw maintain material integrity?

Flying cut off saws avoid thermal stress by using mechanically driven blades, preserving the microstructure of metals like aluminum or titanium. Lubrication systems further minimize friction-induced heating. For reactive metals such as zirconium, inert gas shrouds are added to prevent oxidation during cutting, ensuring compliance with nuclear industry standards.

What industries benefit most from flying saw systems?

Flying saw systems are vital in automotive, aerospace, and construction, where high-speed, precise cutting of materials like stainless steel and composites is critical. The medical device industry also relies on them for cutting bio-compatible titanium rods used in orthopedic implants, where surface quality affects osseointegration.

Can a flying cut off machine handle coated materials?

Yes, makina fluturuese prerëse use specialized blades to slice coated materials like galvanized steel or powder-coated aluminum without damaging protective layers. For solar panel frames with anodized aluminum surfaces, non-contact blade guides prevent scratches that could reduce corrosion resistance.

Why choose a high speed cold saw over thermal cutting?

High speed cold saws prevent HAZs and material warping, essential for applications like medical device manufacturing where titanium’s biocompatibility must remain intact. In aerospace, cold-cut aluminum components retain their fatigue life, which is critical for aircraft longevity.

What safety features are critical for flying saw cutter operations?

Flying saw cutter systems integrate blade guards, emergency brakes, and dust extraction to protect operators, especially when cutting materials like magnesium alloys prone to sparking. For composite materials, HEPA filters capture hazardous micro-particles, ensuring compliance with occupational health regulations.

From flying cut off saws te sharra të ftohta me shpejtësi të lartë, cold cutting technologies redefine precision manufacturing by balancing speed with material preservation. As industries increasingly adopt alloys and composites—from titanium-aluminum hybrids in aviation to CFRP in automotive lightweighting—these systems will continue to evolve. Innovations such as AI-driven predictive maintenance, eco-friendly dry-cutting systems, and hybrid blade coatings promise to further elevate their role in sustainable, high-efficiency production. The future lies in integrating these tools with digital twins and IoT platforms, enabling real-time optimization across global supply chains.

-

Revolutionizing Pipe Production with Modern MachineryLajmeJun.04,2025

-

Precision in Plastic Injection MoldersLajmeJun.04,2025

-

Precision Cutting with Flying Shear TechnologyLajmeJun.04,2025

-

Portable Metal Roof Roll Forming: Revolutionizing On-Site FabricationLajmeJun.04,2025

-

Mastering Pipe Cutting Laser in Modern FabricationLajmeJun.04,2025

-

Innovations in Welded Gas Pipe TechnologyLajmeJun.04,2025