Mastering Pipe Cutting Laser in Modern Fabrication

The industrial manufacturing sector continues to evolve with advanced machinery and techniques that enhance precision, efficiency, and durability. Among the most critical technologies are зварка труб, tubing laser cutting machines, лазер для рэзкі труб, трубапракатны станок ручной, і automated pipe cutting machine. These tools play pivotal roles in construction, energy, automotive, and aerospace industries, ensuring high-quality output and streamlined workflows. This comprehensive guide explores their applications, advantages, and answers common industry questions.

Revolutionizing Production with Tubing Laser Cutting Machines

Tubing laser cutting machines have transformed metal fabrication by delivering unparalleled accuracy and speed. These machines utilize high-intensity laser beams to cut through metal tubes with minimal kerf, reducing material waste. Their non-contact method prevents deformation, making them ideal for intricate designs in automotive exhaust systems, medical devices, and architectural frameworks. Advanced models incorporate CNC (Computer Numerical Control) technology, allowing for programmable patterns and repeatable precision. The ability to process various metals, including stainless steel and aluminum, further broadens their industrial applicability.

Precision Engineering with Pipe Cutting Laser

A лазер для рэзкі труб excels in delivering clean, burr-free cuts, eliminating the need for secondary finishing processes. This technology is indispensable in industries requiring exact tolerances, such as aerospace and shipbuilding. Lasers can handle pipes of diverse diameters and thicknesses, adapting to complex geometries with ease. Fiber lasers, in particular, offer energy efficiency and faster processing times compared to traditional CO₂ lasers. The integration of automated feeding systems enhances productivity, making laser cutting a preferred choice for high-volume manufacturing.

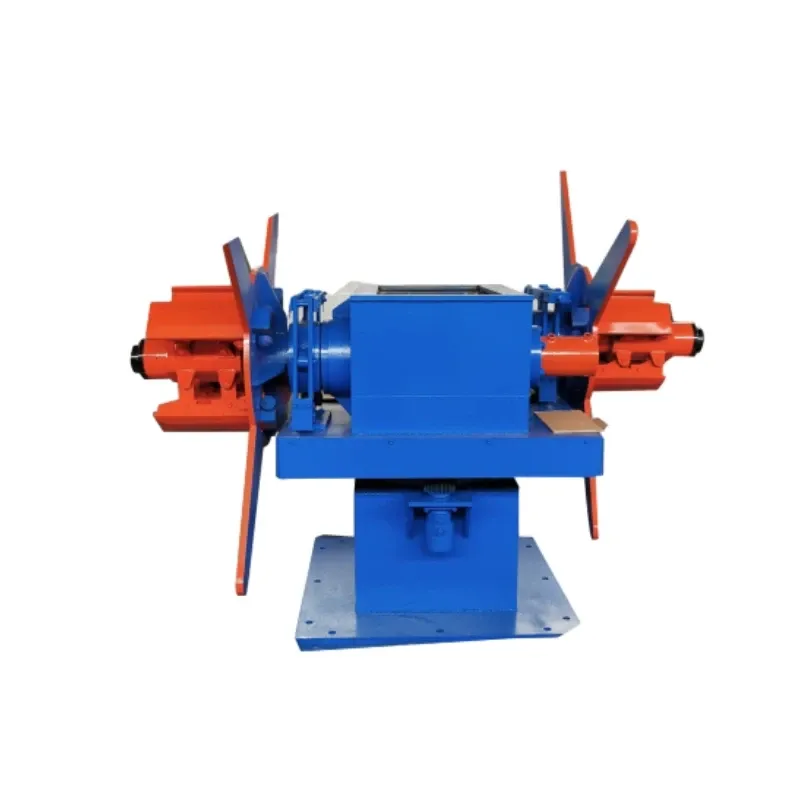

Versatility of Manual Pipe Rolling Machine

For workshops and small-scale operations, the трубапракатны станок ручной provides unmatched flexibility. Operators manually adjust rollers to bend pipes into custom radii, catering to unique project requirements. While slower than automated alternatives, these machines are cost-effective and ideal for prototyping or low-volume production. Their simplicity reduces maintenance needs, and they can process a wide range of materials, from thin-walled tubing to thicker structural pipes.

Efficiency in Automation: Automated Pipe Cutting Machine

The automated pipe cutting machine represents the pinnacle of industrial efficiency, combining speed with precision. These systems are programmable to execute repetitive cuts with minimal human intervention, ensuring uniformity across large batches. Advanced sensors and software optimize material usage, reducing scrap and lowering production costs. Industries such as energy infrastructure and heavy machinery rely on these machines to handle large-diameter pipes and high-strength alloys. The shift toward Industry 4.0 has further enhanced their capabilities, with IoT-enabled diagnostics and real-time performance monitoring.

FAQs About Pipe Cutting Laser in Modern Fabrication

What safety protocols are essential for pipes welding in confined spaces?

Working in confined spaces during зварка труб requires stringent safety measures, including proper ventilation to dissipate toxic fumes, fire-resistant clothing, and continuous air quality monitoring. Welding in such environments often necessitates permits and trained spotters to ensure emergency readiness. Additionally, grounding the workpiece and using insulated tools prevent electrical hazards, while respirators protect against metal particulate inhalation.

How do tubing laser cutting machines handle reflective materials like copper?

Tubing laser cutting machines can process reflective materials like copper by adjusting laser wavelengths or using specialized beam delivery systems. Fiber lasers with shorter wavelengths are more effective, as they reduce reflectivity and improve absorption. Some systems also employ anti-reflective coatings or assist gases like nitrogen to enhance cut quality. Operators must calibrate power settings carefully to avoid beam deflection and ensure consistent results.

What are the maintenance requirements for a pipe cutting laser?

Regular maintenance of a лазер для рэзкі труб includes cleaning optical lenses to prevent beam distortion, checking alignment for accuracy, and replacing consumables such as nozzles and filters. Cooling systems must be monitored to prevent overheating, and lubrication of moving parts ensures smooth operation. Scheduled software updates and calibration checks are equally critical to maintain peak performance and extend the machine’s lifespan.

Can a manual pipe rolling machine achieve tight-radius bends?

While a трубапракатны станок ручной is versatile, achieving tight-radius bends depends on the material’s thickness and ductility. Thinner pipes are more pliable, allowing for sharper curves, but thicker materials may require incremental adjustments to avoid kinking. Operators often use mandrels or internal supports to maintain pipe integrity during bending. For complex shapes, multiple passes with gradual roller adjustments yield the best results.

What industries benefit most from automated pipe cutting machine technology?

The automated pipe cutting machine is indispensable in sectors demanding high precision and volume, such as oil and gas (for pipeline networks), construction (structural steelwork), and automotive (exhaust systems). Its ability to process diverse materials—from carbon steel to titanium—makes it equally valuable in aerospace and shipbuilding. Automation reduces labor costs and accelerates production timelines, meeting the demands of large-scale infrastructure projects.

This exploration underscores how зварка труб, tubing laser cutting machines, лазер для рэзкі труб, трубапракатны станок ручной, і automated pipe cutting machine collectively drive innovation in industrial fabrication. By leveraging these technologies, manufacturers achieve superior quality, efficiency, and adaptability in an increasingly competitive landscape.

-

Revolutionizing Pipe Production with Modern MachineryНавіныJun.04,2025

-

Precision in Plastic Injection MoldersНавіныJun.04,2025

-

Precision Cutting with Flying Shear TechnologyНавіныJun.04,2025

-

Portable Metal Roof Roll Forming: Revolutionizing On-Site FabricationНавіныJun.04,2025

-

Innovations in Welded Gas Pipe TechnologyНавіныJun.04,2025