Precision Cutting with Flying Shear Technology

The metal fabrication industry relies on advanced cutting technologies to achieve high precision, efficiency, and productivity. Among the most critical machines are the flying saw, flying shear, flying shear machine, guillotine metal shear, і гідраўлічная машына для рэзкі металу. These tools play pivotal roles in various industries, including automotive, aerospace, construction, and manufacturing. This comprehensive guide explores their applications, advantages, and answers common technical questions.

Versatility of Flying Shear

A flying shear is an essential tool for cutting metal sheets, strips, and bars in continuous processing lines. This machine operates while moving alongside the material, allowing for uninterrupted production. The flying shear is ideal for applications requiring high-speed cutting, such as steel mills and metal fabrication plants. Its ability to handle various materials, including aluminum, stainless steel, and carbon steel, makes it a versatile solution for diverse industrial needs. Advanced models feature programmable controls, enabling precise adjustments for different material thicknesses and cutting patterns.

Advanced Automation with Flying Shear Machine

The flying shear machine represents the pinnacle of automated cutting technology, combining speed with precision. These machines are equipped with advanced sensors and CNC (Computer Numerical Control) systems, ensuring consistent cuts across large production runs. The flying shear machine is widely used in the aerospace and automotive industries, where tight tolerances and high-quality finishes are paramount. Its ability to integrate with other production line equipment further enhances efficiency, reducing manual intervention and optimizing workflow.

Precision Cutting with Guillotine Metal Shear

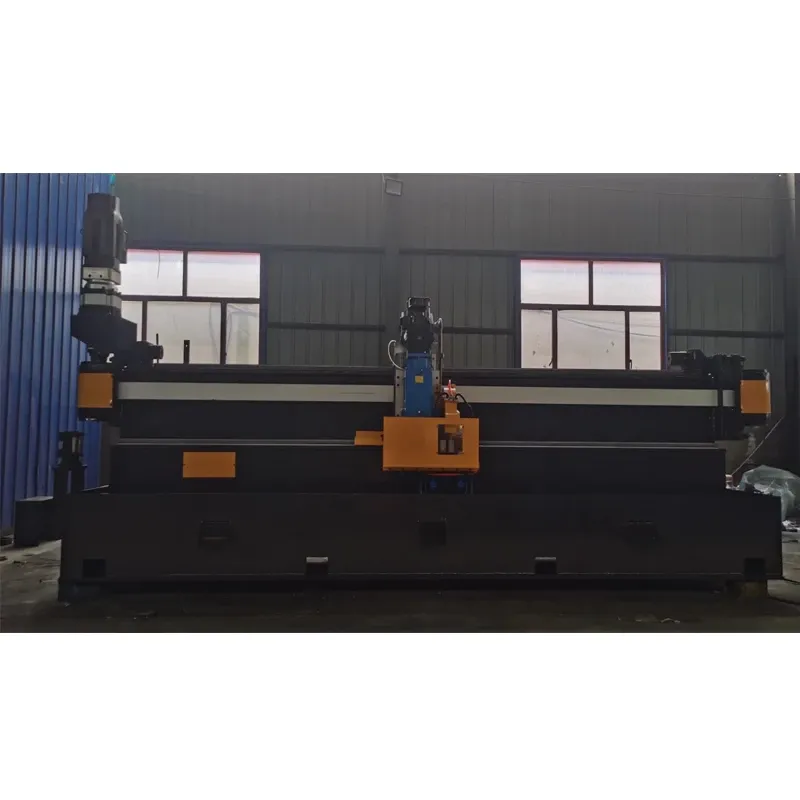

The guillotine metal shear is a robust machine designed for straight-line cutting of metal sheets and plates. Known for its simplicity and reliability, the guillotine metal shear uses a sharp blade to make clean, precise cuts with minimal material distortion. This machine is ideal for workshops and fabrication facilities that require high-volume cutting of thick materials. Modern guillotine metal shear models feature hydraulic or pneumatic systems, allowing for effortless operation and consistent performance. Their durability and low maintenance requirements make them a staple in metalworking industries.

Power and Performance of Hydraulic Metal Shear Machine

The гідраўлічная машына для рэзкі металу is a powerhouse in metal fabrication, offering unmatched cutting force and precision. Utilizing hydraulic pressure, this machine can effortlessly shear through thick metal plates, bars, and structural components. The гідраўлічная машына для рэзкі металу is particularly suited for heavy-duty applications, such as shipbuilding, construction, and industrial manufacturing. Its adjustable blade clearance and stroke control ensure optimal cutting performance for various material types and thicknesses. Additionally, safety features like overload protection and emergency stop mechanisms enhance operator safety during high-intensity operations.

FAQs About Cutting with Flying Shear Technologies

What are the key advantages of using a flying saw in continuous production lines?

The flying saw offers several advantages in continuous production environments. Its ability to cut moving materials without stopping the production line significantly reduces downtime and increases overall efficiency. The synchronized movement ensures precise cuts, minimizing material waste and improving product quality. Additionally, the flying saw can handle a wide range of materials and diameters, making it adaptable to various manufacturing needs. Advanced models feature automatic feed systems and programmable controls, further enhancing productivity and reducing manual labor.

How does a flying shear differ from traditional stationary shears in metal processing?

Unlike traditional stationary shears, the flying shear operates while moving alongside the material, enabling continuous cutting without interrupting the production flow. This capability is particularly beneficial in high-speed manufacturing processes, where stopping the line for each cut would be impractical. The flying shear also offers greater flexibility, as it can be adjusted to cut different lengths and patterns on the fly. Its integration with automated systems allows for real-time monitoring and adjustments, ensuring consistent quality and reducing the risk of errors.

What maintenance practices are essential for a flying shear machine to ensure longevity?

Regular maintenance is crucial to keep a flying shear machine operating at peak performance. Key practices include lubricating moving parts to reduce wear, inspecting blades for sharpness and alignment, and checking hydraulic or pneumatic systems for leaks or pressure drops. Cleaning the machine to remove metal debris and dust prevents buildup that could affect performance. Additionally, calibrating sensors and CNC controls ensures accurate cutting and minimizes material waste. Scheduled downtime for thorough inspections and part replacements can prevent unexpected breakdowns and extend the machine's lifespan.

What types of materials can a guillotine metal shear effectively cut?

The guillotine metal shear is capable of cutting a wide range of materials, including mild steel, stainless steel, aluminum, and copper. Its robust design allows it to handle thick plates and sheets, making it suitable for heavy-duty applications. The cutting capacity depends on the machine's size and power, with larger models capable of shearing through materials several inches thick. For optimal results, operators should ensure the blade is sharp and properly aligned, and the material is securely clamped during cutting to prevent distortion or uneven edges.

What safety features should operators look for in a hydraulic metal shear machine?

Safety is paramount when operating a гідраўлічная машына для рэзкі металу. Essential features include two-hand operation controls to prevent accidental activation, emergency stop buttons for immediate shutdown, and light curtains or guards to protect operators from moving parts. Overload protection systems prevent the machine from exceeding its capacity, reducing the risk of equipment failure. Regular safety training for operators is also critical, covering proper handling techniques, maintenance procedures, and emergency protocols. Ensuring the work area is clear of obstructions and using personal protective equipment (PPE) further minimizes hazards during operation.

This exploration highlights how flying saw, flying shear, flying shear machine, guillotine metal shear, і гідраўлічная машына для рэзкі металу technologies drive innovation in metal fabrication. By leveraging these advanced tools, manufacturers achieve superior precision, efficiency, and safety, meeting the demands of modern industrial applications.

-

Revolutionizing Pipe Production with Modern MachineryНавіныJun.04,2025

-

Precision in Plastic Injection MoldersНавіныJun.04,2025

-

Portable Metal Roof Roll Forming: Revolutionizing On-Site FabricationНавіныJun.04,2025

-

Mastering Pipe Cutting Laser in Modern FabricationНавіныJun.04,2025

-

Innovations in Welded Gas Pipe TechnologyНавіныJun.04,2025