flying saw

The Flying Saw Revolutionizing Precision Cutting

In the ever-evolving landscape of modern manufacturing, the demand for precision, efficiency, and versatility is greater than ever. Among the various tools that have emerged to meet these demands, the flying saw stands out as a remarkable innovation. This advanced cutting technology has not only enhanced productivity in various industries but has also set new standards for precision and quality. In this article, we will explore the concept, operation, and applications of the flying saw, shedding light on its significance in today’s manufacturing world.

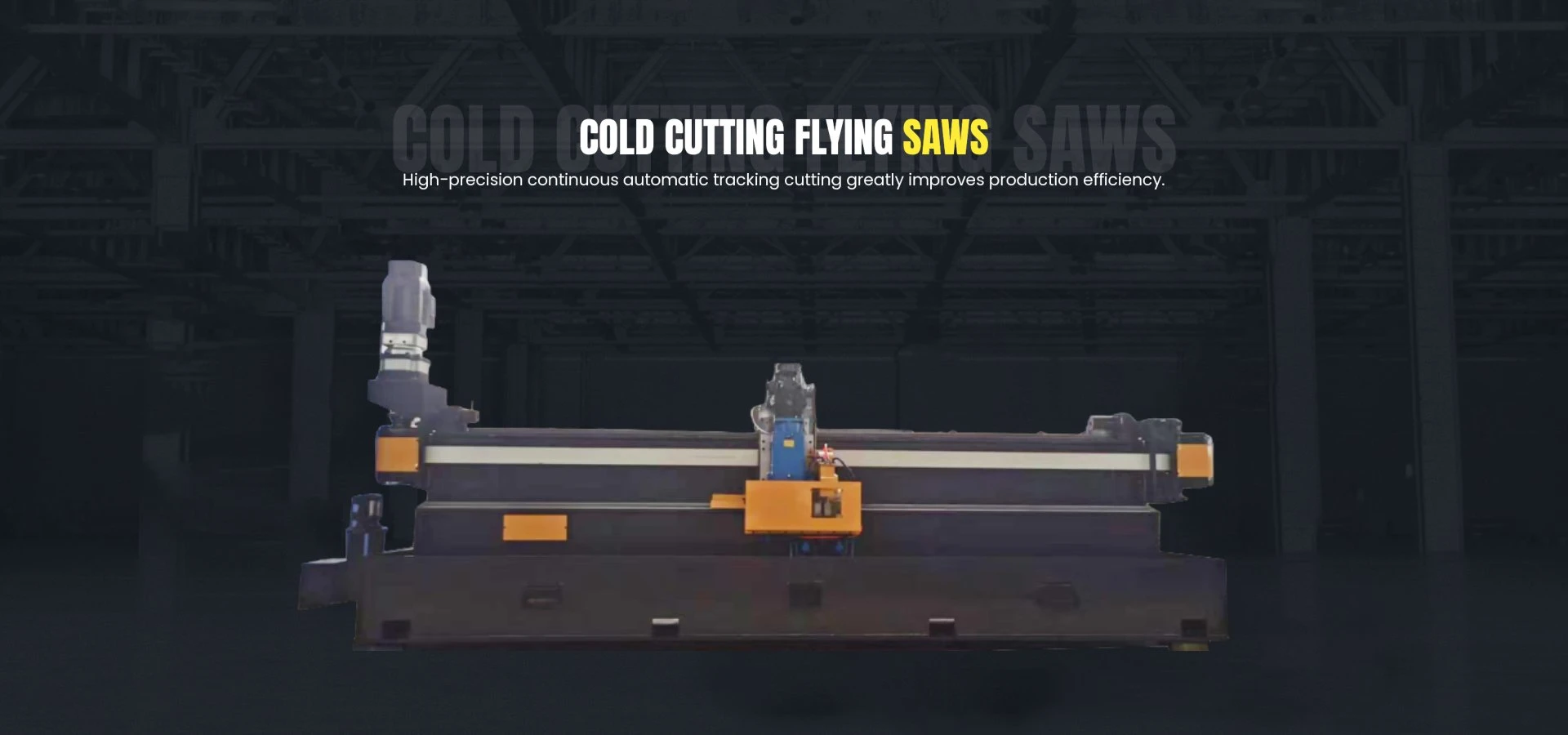

What is a Flying Saw?

At its core, a flying saw is a specialized cutting tool designed for the high-speed, precise cutting of materials, particularly in industrial production environments. Unlike traditional saws that rely on a stationary platform, the flying saw employs an innovative mechanism that allows it to fly to the cutting location. This enables it to cut materials quickly while minimizing waste and maximizing efficiency.

The technology behind the flying saw typically involves a combination of computer numerical control (CNC) and cutting-edge motion control systems. This integration allows for rapid adjustments in speed and position, enabling the saw to operate with remarkable accuracy even when dealing with complex shapes and varying material thicknesses.

Operational Mechanism

The operational efficiency of the flying saw is impressive. Once a material enters the cutting zone, a sensor triggers the saw’s activation. The saw then moves swiftly to the designated cutting position, executes the cut with precision, and retreats back to its original position. This rapid operation reduces cycle times and increases throughput, which is paramount in high-demand production scenarios.

Moreover, the flying saw is often equipped with advanced safety features to ensure the operator's safety. These features include automated shutdown systems and protective barriers, which help minimize the risk of accidents.

Applications Across Industries

flying saw

The versatility of the flying saw is one of its prime advantages, allowing it to be utilized in various sectors

. In the metalworking industry, flying saws are extensively used for cutting metal bars, sheets, and profiles. Their ability to deliver clean cuts reduces the need for further processing, saving both time and cost.In the construction sector, the flying saw can efficiently cut concrete and other construction materials, making it invaluable for precast concrete manufacturers. The precision offered by these saws ensures that components fit together seamlessly, reducing the potential for structural issues.

Moreover, the flying saw has found applications in the woodworking industry. It can be used for cutting lumber and engineered wood products with high accuracy, minimizing waste and optimizing material utilization. As sustainable practices become more critical, tools that maximize the use of raw materials, like the flying saw, are increasingly sought after.

Advantages of the Flying Saw

The flying saw comes with a multitude of advantages that contribute to its growing adoption. First and foremost is its unmatched precision. The ability to execute intricate cuts without the risk of chipping or tearing makes it ideal for applications demanding high-quality finishes.

Additionally, the flying saw's speed translates to enhanced productivity; companies can achieve higher output with less manual labor. This increased efficiency not only reduces operational costs but also allows for quicker turnaround times, a necessary factor in today’s competitive market.

Furthermore, with the integration of CNC technology, the flying saw can be programmed for various cutting patterns, making it adaptable to different projects. This flexibility is essential for manufacturers who need to pivot quickly to meet changing market demands or custom orders.

Conclusion

As industries continue to strive for greater efficiency, precision, and adaptability, tools like the flying saw are leading the charge. By revolutionizing the way materials are cut, it enhances manufacturing processes and supports the ever-growing demand for high-quality products. As we move further into an era defined by technological advancement, the flying saw will undoubtedly play a significant role in shaping the future of precision cutting, proving itself to be an indispensable asset in modern manufacturing.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|line pipe steel&welded gas pipeNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|High Precision&Automated SolutionsNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua Machinery Equipment Manufacturing Co., Ltd.NewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025