homemade roll forming machine

The Art of Homemade Roll Forming Machines

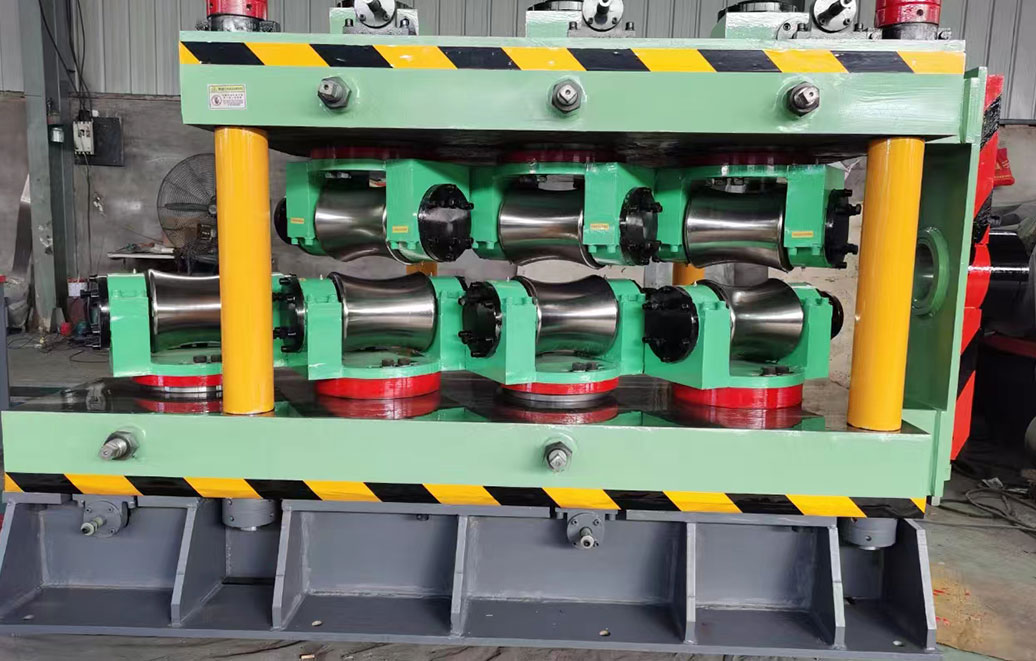

In the world of metal fabrication and production, the roll forming machine stands as a remarkable tool, transforming flat metal strips into intricate shapes with precise efficiency. While many industries rely on large-scale, commercially manufactured machinery, there is a growing trend towards building homemade roll forming machines. This approach not only allows for greater customization but also serves as an engaging project for hobbyists and professionals alike.

Understanding Roll Forming

Roll forming is a continuous bending operation where a long strip of metal is passed through successive pairs of rollers. Each pair of rollers shapes the metal gradually until the desired profile is achieved. This technique is widely used in the construction and automotive industries to produce items like roof panels, framing, and various structural components.

Benefits of Homemade Roll Forming Machines

1. Customization One of the primary advantages of building a homemade roll forming machine is the ability to tailor it to specific needs. Whether you're creating a unique metal profile for artistic endeavors or specific engineering applications, a customized machine allows for flexibility in design.

2. Cost-Effective Industrial roll forming machines can be prohibitively expensive, often costing thousands of dollars. By constructing your own, you can significantly reduce costs, using readily available materials and components.

3. Skill Development Designing and building a roll forming machine enhances your technical skills and knowledge in metalworking. It encourages problem-solving, creativity, and hands-on experience with tools and machinery.

4. Sustainability Homemade machines can utilize scrap metal and leftover materials from other projects, promoting sustainability and reducing waste. Repurposing materials not only benefits the environment but also adds character to your creations.

Designing Your Machine

homemade roll forming machine

When it comes to creating a homemade roll forming machine, there are several key components to consider

- Frame The structure must be robust enough to withstand the forces applied during the forming process. Steel or heavy-duty aluminum are common choices for the frame material.

- Rollers The number and design of rollers depend on the desired shape of the finished product. You can create your own rollers using a lathe or by machining existing metal rods.

- Drive Mechanism A reliable way to feed the metal strip through the rollers is essential. This can be accomplished using a system of gears, pulleys, or an electric motor, depending on your mechanical skills and the power requirements.

- Adjustability Incorporating adjustable rollers is crucial for accommodating different thicknesses of metal and various profile shapes.

Safety Considerations

Safety must always be a priority when operating machinery, especially homemade equipment. Wear appropriate safety gear, including gloves, goggles, and ear protection. Ensure that your machine is well-maintained and that all moving parts are adequately shielded to prevent accidents.

Conclusion

Creating a homemade roll forming machine opens up a world of possibilities for metal fabrication enthusiasts. Not only does it enable the production of customized components, but it also provides an opportunity to learn and innovate. As the DIY spirit continues to flourish, more individuals are discovering the satisfaction of building their own tools and equipment, unlocking new creative potential in the process. Whether you’re a seasoned metalworker or just starting, assembling a homemade roll forming machine can be both a worthwhile endeavor and a gateway to an exciting new journey in metalworking.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|line pipe steel&welded gas pipeNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|High Precision&Automated SolutionsNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua Machinery Equipment Manufacturing Co., Ltd.NewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025