Manual Hose Pipe Crimping Equipment for Efficient and Reliable Hose Assembly

Manual Hose Pipe Crimping Machines A Comprehensive Overview

In the realm of fluid transfer and hydraulic systems, the reliability and efficiency of hose connections are paramount. A crucial element in ensuring the integrity of these connections is the crimping process. Manual hose pipe crimping machines serve as indispensable tools in both industrial and DIY settings, providing an effective and durable method for securing hose fittings. This article explores the functionality, benefits, and operational guidelines of manual hose pipe crimping machines.

Understanding Hose Crimping

Hose crimping involves compressing a metal sleeve or fitting onto the end of a hose to create a secure connection. This process is essential for preventing leaks and ensuring that hoses can withstand high pressures commonly seen in hydraulic and pneumatic applications. Manual hose pipe crimping machines facilitate this process, allowing users to achieve a strong crimp without the need for electric power.

Working Mechanism

Manual crimping machines typically feature a clamp mechanism that holds the hose and fitting in place. The operator uses a lever or handle to apply pressure, forcing the fitting tightly against the hose. Most machines are designed with adjustable dies that accommodate various hose sizes and types. Operators can easily switch out dies to fit different applications, enhancing versatility.

While manual machines require more physical effort than their hydraulic or electric counterparts, they are often equipped with features that streamline operation. For instance, some models include quick-change dies or built-in measuring gauges to ensure accuracy in crimping.

Advantages of Manual Hose Pipe Crimping Machines

1. Cost-Effectiveness Manual crimping machines are generally less expensive than electric or hydraulic models. For smaller workshops or individuals working on projects with lower volumes, this makes manual machines a practical choice.

2. Portability Their lightweight and compact design make manual crimping machines easy to transport. This mobility is particularly beneficial for fieldwork or projects that require on-site assembly.

3. Simplicity of Use Manual machines are straightforward to operate, often requiring minimal training. The mechanics are easy to understand, and with some practice, users can achieve consistently good results.

4. Reliability Without reliance on electricity or complex hydraulic systems, manual crimping machines are less likely to suffer from mechanical failures. This reliability makes them ideal for environments where power sources may be limited.

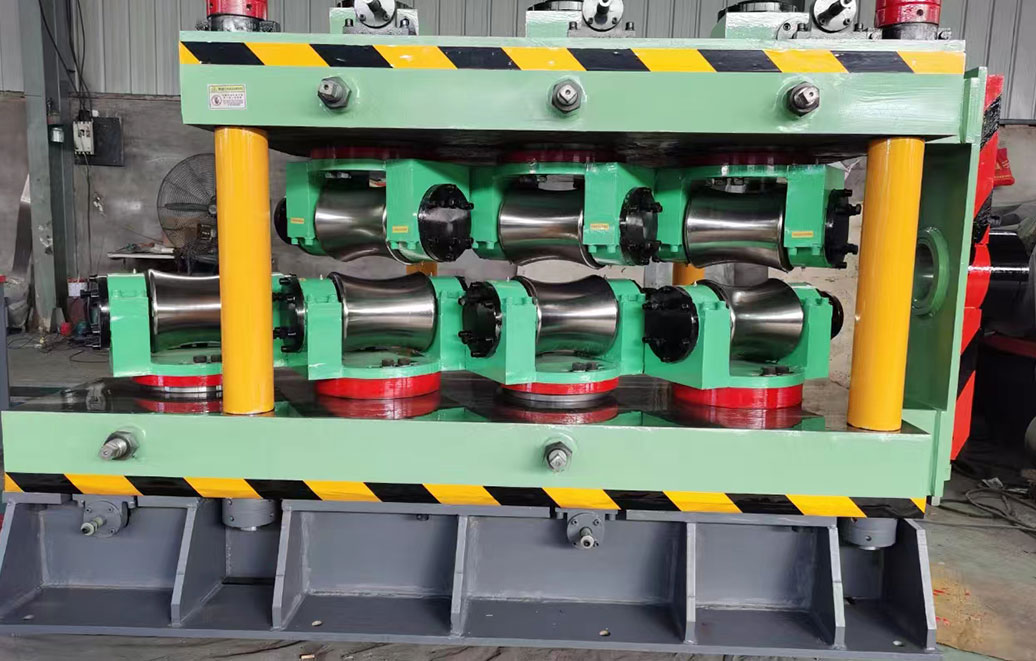

manual hose pipe crimping machine

5. Precision Many manual crimping machines allow for precise control over the crimping process. This control can lead to better-quality connections, reducing the risk of leaks and failures.

Applications

Manual hose pipe crimping machines are widely used across various industries. In agriculture, they are essential for creating durable connections in irrigation systems. The automotive industry relies on these machines for securing fuel and hydraulic hoses. Additionally, manufacturing and construction applications benefit from reliable hose connections, ensuring smooth operations and safety in equipment.

Best Practices for Effective Crimping

To achieve optimal results with a manual hose pipe crimping machine, consider the following best practices

- Proper Selection of Dies Always choose the correct die size for the hose and fitting. Incorrect die selection can lead to weak or ineffective crimping.

- Preparation of Hose Ends Ensure that the hose ends are clean and free of debris before crimping. Contaminants can compromise the crimp quality and lead to failures.

- Consistent Pressure Application Apply steady pressure while crimping to maintain uniformity. Inconsistent pressure can result in uneven fittings, increasing the risk of leaks.

- Regular Maintenance Keep the machine well-maintained by inspecting it regularly for wear and tear. Lubricate moving parts as necessary to ensure smooth operation.

Conclusion

In summary, manual hose pipe crimping machines are essential tools for anyone involved in fluid transfer applications. Their cost-effectiveness, portability, and reliability make them a favorite among mechanics, engineers, and DIY enthusiasts. By understanding their operation and adhering to best practices, users can achieve high-quality hose connections that ensure safety and efficiency in various applications. Whether in a workshop or on a job site, mastering the use of a manual hose pipe crimping machine can significantly enhance productivity and quality of work.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|line pipe steel&welded gas pipeNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|High Precision&Automated SolutionsNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua Machinery Equipment Manufacturing Co., Ltd.NewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025