Stainless Steel Pipe Production Equipment Supplier for Efficient Manufacturing Solutions

Stainless Steel Pipe Making Machine Manufacturer A Key Player in Modern Manufacturing

In the realm of modern manufacturing, stainless steel has emerged as a material of choice due to its durability, resistance to corrosion, and ability to maintain structural integrity under extreme conditions. The demand for stainless steel products—ranging from kitchenware to industrial components—has led to an increased need for specialized machinery that can produce these products efficiently. Enter the stainless steel pipe making machine manufacturer, a vital cog in the supply chain of numerous industries.

Understanding Stainless Steel Pipe Making Machines

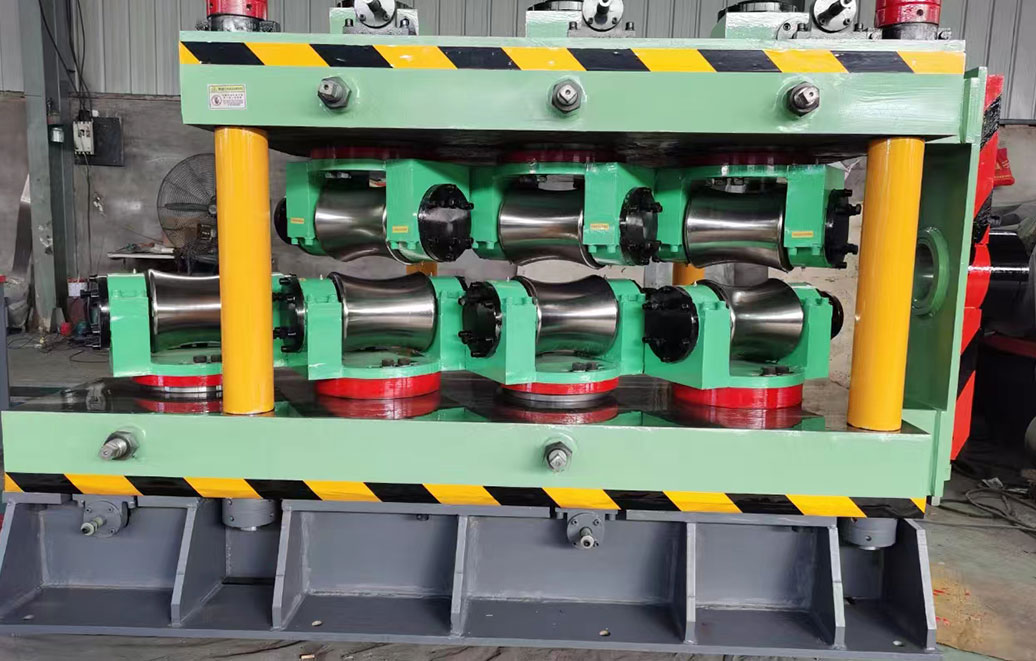

Stainless steel pipe making machines are designed for the production of stainless steel pipes and tubes, a material that finds applications in various sectors, including construction, automotive, aerospace, and chemical processing. These machines are engineered to handle the raw stainless steel material, typically in coil form, and transform it into finished pipes through a series of processes—including slitting, forming, welding, and cutting.

The manufacturing process begins with feeding stainless steel coils into the machine. The coils are first uncoiled and then slit into narrower strips, which are subsequently formed into a tubular shape. One of the most critical steps is the welding process, where the edges of the strip are joined together to create a seamless or welded pipe. Advanced techniques such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding are often employed, ensuring high-quality welds that maintain the integrity of the pipe.

Quality and Customization

One of the defining features of a reliable stainless steel pipe making machine manufacturer is their commitment to quality

. Manufacturers must adhere to stringent industry standards to ensure that the pipes produced are not only durable but also meet specific regulatory requirements. This necessitates the use of high-grade materials and cutting-edge technology in machine design and fabrication.Moreover, customization is increasingly becoming a valuable proposition. Different industries may require specific types of pipes with unique dimensions, wall thicknesses, and finishes. A reputable manufacturer will offer tailored solutions to meet these diverse needs, allowing companies to optimize their production processes and enhance their product offerings. This adaptability is crucial in today’s fast-paced market where customer demands are continually evolving.

stainless steel pipe making machine manufacturer

Technology and Innovation

The landscape of manufacturing is rapidly changing, driven by advancements in technology. The stainless steel pipe making machine manufacturer must stay abreast of these changes to remain competitive. Automation plays a significant role in modern pipe production, reducing labor costs and increasing efficiency. Machines equipped with computer numerical control (CNC) systems can operate with minimal human intervention, resulting in higher precision and faster production rates.

Moreover, manufacturers are increasingly embracing Industry 4.0 concepts, incorporating IoT (Internet of Things) devices into their production lines. This integration allows for real-time monitoring of machine performance and product quality, helping manufacturers identify potential issues before they escalate, thereby reducing downtime and waste.

Environmental Considerations

The focus on sustainability has also influenced the stainless steel pipe making industry. Manufacturers are now more aware of their environmental impact and are actively seeking ways to minimize it. This includes optimizing energy consumption during production and implementing recycling programs for scrap metal. By adopting greener practices, manufacturers can appeal to eco-conscious consumers and comply with environmental regulations.

Conclusion

The role of stainless steel pipe making machine manufacturers is pivotal in today’s manufacturing landscape. They not only produce the machinery that enables the creation of essential industrial products but also drive innovation and sustainability within the industry. As the demand for high-quality stainless steel pipes continues to rise, these manufacturers stand at the forefront, equipped with the technology, expertise, and commitment to meet the evolving needs of their clients. In an era of rapid change, their ability to adapt and innovate will ultimately determine their success and, by extension, the industries they support.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|line pipe steel&welded gas pipeNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|High Precision&Automated SolutionsNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua Machinery Equipment Manufacturing Co., Ltd.NewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025