straightening machine manufacturers

Understanding Straightening Machine Manufacturers A Key to Precision Metal Processing

In the realm of metal processing, straightening machines play a pivotal role. These specialized machines are designed to correct and refine the shapes of metal workpieces, ensuring they meet strict dimensional tolerances. As industries strive for enhanced efficiency and productivity, the importance of high-quality straightening machines cannot be overstated. This article delves into the landscape of straightening machine manufacturers, examining their importance, the technologies they utilize, and the evolving trends within the industry.

The Role of Straightening Machines

Straightening machines are crucial in various industries, including automotive, aerospace, and construction. They address the common issue of material distortion that occurs during processes such as rolling, welding, or heat treatment. By employing these machines, manufacturers can ensure that metal parts such as sheets, rods, and bars maintain uniformity and structural integrity, critical factors in maintaining quality standards.

Types of Straightening Machines

There are several types of straightening machines, including roller straighteners, press straighteners, and mechanical straighteners. Roller straighteners use a series of rollers to gradually realign the metal, making them ideal for continuous operations. Press straighteners apply direct force to the workpiece, allowing for substantial correction, while mechanical straighteners offer versatility for various thicknesses and types of materials.

The Importance of Choosing the Right Manufacturer

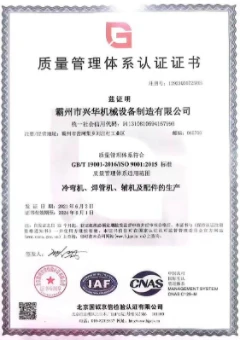

Selecting the right manufacturer for straightening machines is essential for ensuring quality and reliability. Reputable manufacturers typically emphasize the integration of advanced technologies, customization options, and compatibility with existing production lines. Additionally, they should have a proven track record, with testimonials or case studies showcasing their equipment's performance in real-world applications.

straightening machine manufacturers

Advanced Technologies in Straightening Machines

Modern straightening machines incorporate cutting-edge technology to enhance efficiency and accuracy. Automation, for example, has revolutionized operations by allowing for real-time adjustments and feedback, which minimizes human error and increases throughput. Furthermore, advancements in sensor technology enable precise control over the straightening process, ensuring consistently high-quality results.

Manufacturers are also increasingly adopting Industry 4.0 principles, integrating IoT (Internet of Things) features into their equipment. This connection allows for better monitoring and predictive maintenance, which can significantly reduce downtime and increase productivity. Data analytics plays a crucial role in optimizing the operations of straightening machines, making them smarter and more efficient.

Evolving Trends and Sustainability

The metal processing industry is witnessing a focus on sustainability, prompting manufacturers to seek energy-efficient equipment and greener production processes. Various manufacturers are investing in technologies that reduce waste and energy consumption, catering to the growing demand for environmentally friendly operations. This shift not only aligns with industry regulations but also resonates with consumers' increasing preference for sustainable products.

Moreover, as industries expand globally, straightening machine manufacturers face the challenge of meeting diverse regulatory standards. Adapting to international standards while maintaining compliance is essential for manufacturers aiming to penetrate new markets.

Conclusion

In summary, straightening machine manufacturers are a cornerstone of the metal processing industry. Their commitment to technological innovation, quality, and sustainability enables them to meet the demands of modern manufacturing. By choosing a reputable manufacturer and understanding the capabilities of various straightening machines, stakeholders can significantly enhance their production processes. As the industry continues to evolve, staying informed about trends and advancements will be essential for those seeking to maintain a competitive edge.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|line pipe steel&welded gas pipeNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|High Precision&Automated SolutionsNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua Machinery Equipment Manufacturing Co., Ltd.NewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025