tube mill line

The Tube Mill Line An Indispensable Component in Modern Manufacturing

In the ever-evolving landscape of manufacturing, the tube mill line stands out as a vital component in the production of seamless and welded tubes. These tubes serve a multitude of industries, including construction, automotive, aerospace, and energy, making the efficiency and reliability of the tube mill line paramount. This article delves into the intricacies of tube mill lines, highlighting their significance, operational mechanism, and future trends.

Understanding Tube Mill Lines

A tube mill line is a series of interconnected machines and equipment designed to produce metal tubes from raw material strips or coils. The process begins with uncoiling the metal strip, which is then shaped and welded into tubes. Depending on the specific type of tube required—welded or seamless—different methodologies and machinery are employed.

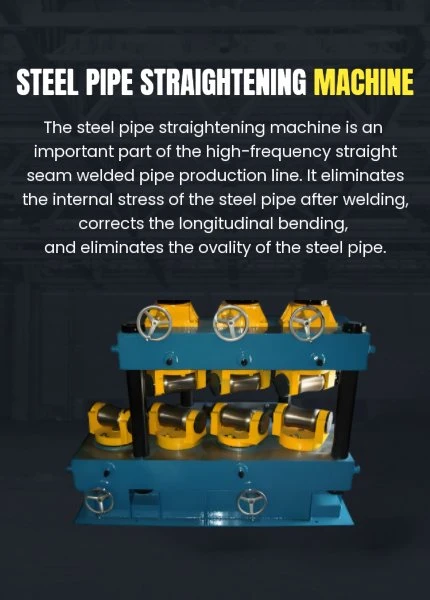

Welded Tube Mills The most common type of tube mill, these systems utilize a process where the edges of the metal strip are heated and pressed together, forming a weld seam. Post-welding, the tube undergoes various stages such as sizing, cutting, and finishing, to ensure that it meets specific standards.

Seamless Tube Mills Conversely, seamless tube production involves more complex processes, including piercing and elongating. A solid billet is heated and then pierced to create a hollow tube, which is further elongated and worked to achieve the desired dimensions.

Operational Mechanism

A typical tube mill line consists of several key components

1. Uncoiler This machine unwinds the raw material, preparing it for processing. 2. Pipe Forming Mill As the material passes through various rollers, it is gradually shaped into a tubular form. 3. Welding Station For welded tubes, this section brings the edges together and employs various welding techniques, such as high-frequency or laser welding, to bond them permanently. 4. Sizing Mill This component ensures that the newly formed tubes adhere to precise diameter specifications. 5. Cut-off Machine Once the necessary length is achieved, the tubes are cut for further processing or delivery. 6. Finishing Equipment This includes processes like polishing, coating, or end machining, which enhance the tube's aesthetic quality and durability.

These machines operate in a synchronized manner, showcasing the importance of well-planned processes and sophisticated technology in ensuring high productivity and quality output.

tube mill line

Applications Across Industries

The versatility of tube mill lines allows them to cater to various sectors

- Construction Steel tubes produced for structural purposes, scaffolding, and plumbing systems. - Automotive Tubes used in vehicle frames, exhaust systems, and fuel lines. - Aerospace High-strength tubes for different aircraft components, ensuring safety and efficiency. - Energy Production of tubes for oil and gas pipelines, often designed to withstand harsh environments.

Each of these applications demands precision and reliability, thereby enhancing the importance of advanced tube mill technologies.

Future Trends

Advancements in technology promise to redefine the landscape of tube mill lines. Automation and robotics are becoming increasingly integrated into these production lines, leading to enhanced efficiency, reduced labor costs, and minimized human errors. Moreover, Industry 4.0 concepts, such as IoT (Internet of Things) and data analytics, are paving the way for smart manufacturing. These technologies can monitor equipment conditions in real-time, leading to predictive maintenance and operational efficiencies.

Sustainability is another pivotal trend. Manufacturers are now focused on reducing waste and energy usage during the tube production process. The adoption of eco-friendly materials and recycling practices is becoming common, which not only meets regulatory standards but also appeals to environmentally conscious consumers.

Conclusion

The tube mill line is an essential pillar of modern manufacturing, providing critical products that drive various industries forward. As technology continues to advance, the efficiency, sustainability, and adaptability of these production lines will only improve. By embracing innovation and leveraging cutting-edge technologies, the future of tube mill manufacturing is not only bright but also vital to the ongoing progress of global manufacturing practices. The ongoing evolution of tube mill lines will ensure they remain at the forefront of production, catering to the diverse needs of an ever-expanding marketplace.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|line pipe steel&welded gas pipeNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|High Precision&Automated SolutionsNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua Machinery Equipment Manufacturing Co., Ltd.NewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025