Metal Deck Roll Forming Equipment for Efficient Construction Solutions and High-Quality Production

Understanding Metal Deck Roll Forming Machines

Metal deck roll forming machines play a pivotal role in the construction industry, providing an efficient means of manufacturing metal decking used in various applications, such as floors, roofs, and other structural components. These machines utilize advanced technology to produce high-quality metal decking with precision, speed, and consistency. In this article, we will explore the functionality, benefits, applications, and considerations when selecting a metal deck roll forming machine.

What is a Metal Deck Roll Forming Machine?

A metal deck roll forming machine is designed to shape metal sheets into specific profiles that are often used in the construction of buildings, commercial facilities, and other structures. The process begins with a flat sheet of metal, typically made of steel or aluminum, which is fed into the machine. The roll forming process involves several stages of bending the metal into the desired shape through a series of rollers set in a specific configuration. The result is a continuous length of decking that can be cut to the required size.

Key Features and Components

Metal deck roll forming machines come equipped with several components that enhance their functionality

1. Uncoiler This device holds the coil of metal sheet and feeds it into the machine smoothly. 2. Roll Forming Section This is the heart of the machine, where the metal is shaped into the desired profile. The design and arrangement of rollers are critical for achieving the correct shape and thickness.

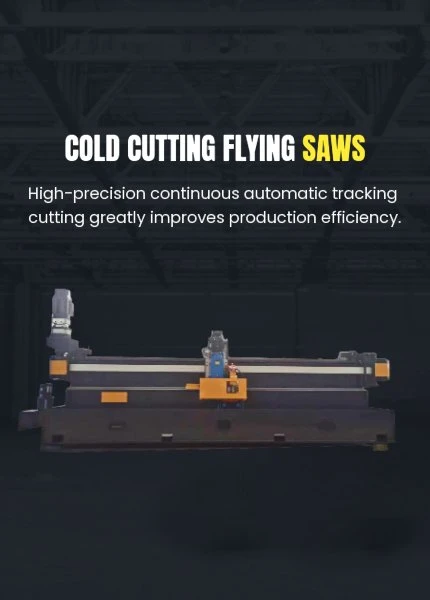

3. Cutting Mechanism After the metal has been formed into the desired shape, it is cut to the specified lengths. This can be done through various methods, including shear cutting or flying cut-off systems.

4. Control System Modern roll forming machines are equipped with advanced digital controls that enable operators to set parameters for speed, length, and thickness. This automation enhances precision and reduces labor costs.

5. Stacker Once the metal decking has been cut, it is typically stacked for further processing or shipping. The stacker arranges the finished products efficiently.

Benefits of Using Metal Deck Roll Forming Machines

1. Efficiency Metal deck roll forming machines significantly reduce production time compared to traditional methods. They can operate at high speeds, producing a large quantity of decking in a short period.

2. Cost-Effective By streamlining the production process and minimizing waste, these machines contribute to lower manufacturing costs. Their consistent output quality also reduces the need for rework.

3. High-Quality Products Roll forming produces metal decking with excellent dimensional accuracy and a superior surface finish, meeting the requirements of stringent industry standards.

4. Versatility These machines can easily be adjusted to produce a variety of decking profiles, allowing manufacturers to cater to diverse customer needs.

metal deck roll forming machine

5. Durability Metal decking is known for its strength and longevity, making it a preferred choice for construction projects. The roll forming process enhances these properties, ensuring products can withstand harsh conditions.

Applications of Metal Decking

Metal decking is widely utilized in various construction applications

- Commercial Buildings Metal decking is often used in the floors and roofs of commercial buildings due to its strength and load-bearing capabilities.

- Industrial Structures Warehouses, factories, and plants benefit from metal decking's durability and resistance to heavy loads.

- Infrastructure Projects Bridges and roadways can also utilize metal decking due to its lightweight yet robust nature.

Considerations When Choosing a Metal Deck Roll Forming Machine

When selecting a metal deck roll forming machine, several factors should be taken into account

1. Production Capacity Consider the volume of decking you intend to produce and choose a machine that meets those demands.

2. Profile Options Look for machines that can accommodate the specific decking profiles required for your projects.

3. Automation Level Higher levels of automation can lead to greater efficiency but may also come with higher initial costs. Assess your budget and operational needs.

4. Warranty and Support Ensure the manufacturer offers reliable customer support and adequate warranty coverage for parts and service.

5. Space Requirements Determine the available space in your facility to accommodate the machinery and ensure proper workflow.

In conclusion, metal deck roll forming machines are indispensable tools in the modern construction industry, enabling producers to manufacture high-quality, durable metal decking efficiently. By understanding the features, benefits, and considerations related to these machines, businesses can make informed decisions that enhance productivity and operational success.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.NewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Manufacturing, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Steel Pipe Manufacturing&Industrial EfficiencyNewsJul.29,2025