Top Manufacturers of Straightening Machines for Precision Metal Processing

The Role of Straightening Machine Manufacturers in Modern Industry

In the rapidly evolving landscape of manufacturing, straightening machines play a pivotal role in ensuring the precision and quality of metal products. These machines are essential for correcting deformities in metal materials, enabling various industries to maintain high standards of production. In this article, we will explore the significance of straightening machine manufacturers in modern industry, the technology behind these machines, and what to consider when selecting a manufacturer.

Understanding Straightening Machines

Straightening machines are designed to restore the original shape of metal workpieces that may have suffered from bending, warping, or other forms of distortion due to manufacturing processes like rolling, forging, or welding. These machines apply force to the material, enabling it to return to its intended dimensions and tolerances. The ability to straighten materials not only improves product quality but also enhances their mechanical properties, making them more suitable for further processing or end-use.

The Importance of Reliable Manufacturers

Straightening machine manufacturers are crucial for supplying high-quality equipment necessary for production efficiency. The choice of a manufacturer can significantly impact a company’s operational effectiveness. A reliable manufacturer ensures that their machines are built with precision engineering, utilizing the latest technology to maximize performance and durability. By investing in high-quality machines, manufacturers can reduce downtime, minimize waste, and enhance overall productivity.

Technology and Innovation

With advancements in technology, the straightening machinery industry has seen significant innovations. Modern straightening machines are equipped with computerized controls and automation features, allowing for greater precision and consistency in the straightening process. Many manufacturers are integrating Artificial Intelligence (AI) and Industry 4.0 technologies into their equipment, enabling real-time monitoring and data analysis to optimize performance.

Moreover, the use of advanced materials in the construction of straightening machines has enhanced their resilience and efficiency. Manufacturers are now producing machines that not only straighten metal but also do so while minimizing energy consumption and reducing environmental impact. This shift toward sustainability is becoming increasingly important, as industries are held to higher standards of environmental responsibility.

straightening machine manufacturers

Selecting the Right Manufacturer

Choosing the right straightening machine manufacturer can be a daunting task, given the plethora of options available in the market. Here are some key factors to consider when making this crucial decision

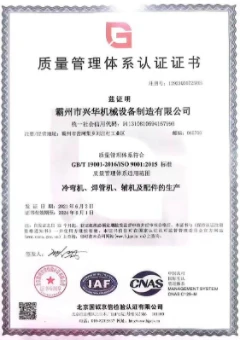

1. Reputation and Experience Look for manufacturers with a solid track record and extensive experience in producing straightening machines. Industry experience often translates to better quality and customer support.

2. Technology and Innovation Evaluate whether the manufacturer is adopting the latest technologies in their machines. Modern features such as automation, digital controls, and energy-efficient designs are indicative of a manufacturer committed to progress.

3. Customization Options Every production line has unique requirements. A great manufacturer should offer customizable solutions to cater to specific needs, improving the overall efficiency of your operations.

4. Customer Support and Service A reliable manufacturer should provide exceptional after-sales support. This includes installation, training, and ongoing maintenance services to ensure your machinery remains in optimal condition.

5. Cost-Effectiveness Price is an important consideration, but it should not be the only factor. Evaluate the total cost of ownership, which includes purchase price, operational efficiency, maintenance costs, and the expected lifespan of the machinery.

Conclusion

As industries continue to face the challenges of high competition and ever-increasing quality standards, the role of straightening machine manufacturers becomes even more critical. Their contributions not only facilitate the production of high-quality metal products but also drive innovation and sustainability within the manufacturing sector. By choosing the right manufacturer, businesses can ensure their operations are equipped with the most advanced and reliable tools available, ultimately enhancing their competitive edge in the market. Investing in quality straightening machines is not just a matter of operational efficiency; it is a strategic decision that can influence a company’s long-term success.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.NewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Manufacturing, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Steel Pipe Manufacturing&Industrial EfficiencyNewsJul.29,2025