Cost Analysis for Straightening Machinery in Today's Market

Understanding Straightening Machine Prices Key Factors and Considerations

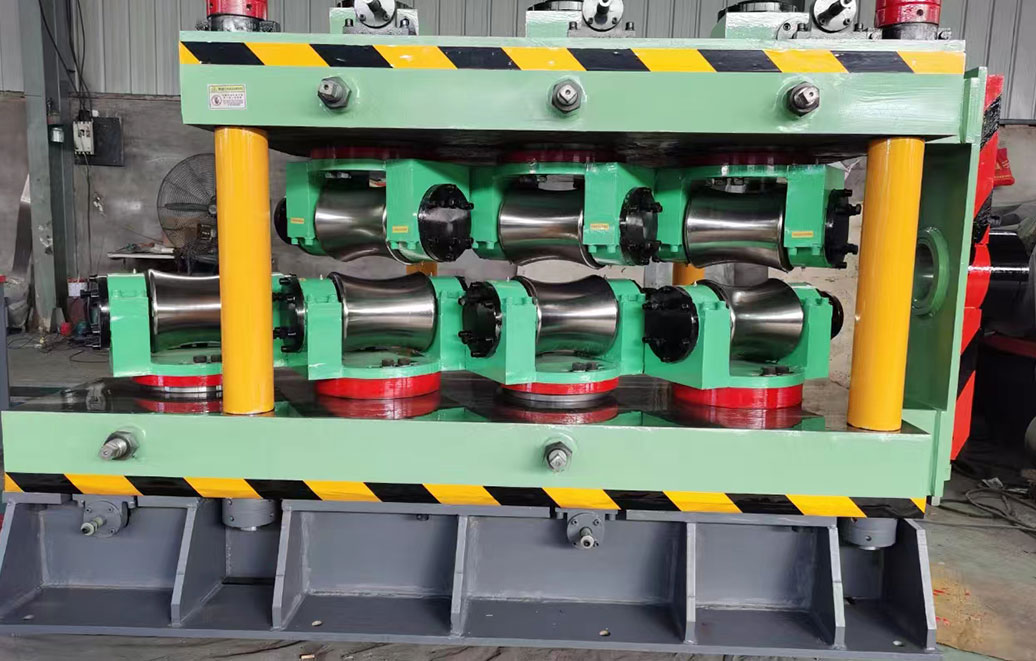

In the world of manufacturing and metalworking, straightening machines play a pivotal role in ensuring that metal products meet the required specifications. These machines are designed to remove bends, twists, and other distortions from metal materials, ultimately improving their quality and usability. However, when it comes to purchasing a straightening machine, one might find themselves grappling with the question What influences the prices of these machines? This article aims to provide insight into the factors affecting straightening machine prices and what potential buyers should consider before making a purchase.

Types of Straightening Machines

First and foremost, it’s crucial to recognize that straightening machines come in various types and models, each designed for specific tasks. Common types include hydraulic straightening machines, mechanical straightening machines, and automated straightening systems. Hydraulic machines are often favored for their capacity to handle large loads and complex shapes, while mechanical machines are more budget-friendly and suitable for simpler tasks. Automated systems, on the other hand, offer precision and efficiency, making them a popular choice for large-scale operations. Each type comes with its own pricing structure based on the technology and features it offers.

Factors Influencing Prices

1. Technology and Features The level of technology incorporated into a straightening machine can significantly impact its price. Advanced features such as CNC (Computer Numerical Control) capabilities, automatic adjustments, and real-time monitoring systems may raise the cost. Machines equipped with state-of-the-art technology provide greater accuracy and efficiency but at a higher initial investment.

straightening machine price

2. Capacity and Size The size and capacity of the machine also play crucial roles in determining its price. Machines that can handle larger and heavier materials typically cost more due to their reinforced construction and higher power requirements. Potential buyers should assess their production needs to determine the appropriate size and capacity, ensuring they invest in a machine that meets their demands without overspending.

3. Brand Reputation and Quality Established brands often command higher prices due to their reputation for quality and reliability. When investing in a straightening machine, it’s essential to consider the track record of the manufacturer. A reputable brand may offer better warranties, customer support, and longevity, yielding a higher return on investment despite the initial cost.

4. Customization Options Some manufacturers offer customization options, allowing buyers to tailor machines to their specific needs. Custom features can include adjustability for different materials, additional safety mechanisms, or enhanced automation. While customization can increase the upfront cost, it can also improve operational efficiency and output quality in the long run.

5. Market Conditions The overall economic climate can also influence straightening machine prices. Factors such as raw material availability, tariffs on imported equipment, and fluctuations in demand for metalworking machinery can affect pricing. Keeping an eye on market trends can help buyers time their purchase for the best possible deal.

Conclusion

Investing in a straightening machine is a significant decision that requires careful consideration of various factors. Understanding the different types of machines available and the elements that contribute to pricing can aid potential buyers in making informed choices. While the initial cost is an important aspect, it’s equally vital to assess how the machine will perform in the long term, the potential for increased productivity, and the overall quality of output. Conducting thorough research and comparing options will not only help in finding a machine that fits within one’s budget but also enhances operational efficiency and product quality in the manufacturing process.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.NewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Manufacturing, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Steel Pipe Manufacturing&Industrial EfficiencyNewsJul.29,2025