tube straightening machine manufacturers

The Importance of Tube Straightening Machines in Manufacturing

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. Among the array of equipment that plays a vital role in achieving these goals, tube straightening machines stand out. These machines are specifically designed to ensure that metal tubes are straightened to exact specifications, which is crucial for various applications, including automotive, aerospace, and construction. This article will explore the significance of tube straightening machines, the leading manufacturers in the industry, and the advancements that have revolutionized this aspect of manufacturing.

Understanding Tube Straightening Machines

Tube straightening machines are specialized devices that rectify bent or warped tubes, transforming them into straight, uniform products essential for subsequent manufacturing processes. They operate by applying mechanical force to the tubes, effectively correcting any deviations in shape. These machines are capable of processing various materials, including steel, aluminum, and copper, making them versatile tools in different sectors.

Applications of Tube Straightening Machines

The applications of straightened tubes are extensive. In the automotive industry, for example, precision-engineered tubes are crucial for the production of exhaust systems, fuel lines, and structural components. Any deviation in tube shape can lead to performance issues or, worse, safety hazards. Similarly, in aerospace applications, the integrity and precision of tube components are vital, as they must withstand extreme conditions without failure.

Moreover, tube straightening is also critical in the construction industry, where straightened tubes are used in scaffolding, piping, and structural frameworks

. The importance of having accurate dimensions cannot be overstated, as it contributes to the overall safety and durability of constructions.Leading Manufacturers in the Industry

tube straightening machine manufacturers

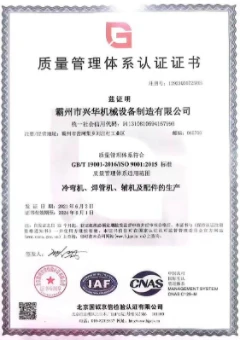

Several manufacturers have emerged as leaders in the tube straightening machine market, each bringing unique innovations and technologies to the forefront. Companies like Schiavi, Kongskilde, and Häusermann are renowned for producing high-quality, reliable machines tailored to meet the diverse needs of manufacturers.

These manufacturers continuously invest in research and development, integrating advanced technologies such as automation and digital monitoring into their machines. These advancements enhance precision and efficiency, ensuring manufacturers can meet stringent production demands.

Advancements in Technology

The evolution of tube straightening machines has been driven by technological advancements. Modern machines often incorporate automation and robotics, allowing for faster and more accurate straightening processes. Automation helps reduce human error, enhances repeatability, and allows manufacturers to optimize their production lines.

Additionally, the integration of sensors and IoT technology has improved monitoring capabilities. Operators can now track the condition of the machines in real-time, predict maintenance needs, and even collect data for quality control. This data-driven approach enables manufacturers to enhance their production processes and reduce downtime, leading to significant cost savings.

Conclusion

In conclusion, tube straightening machines are indispensable in modern manufacturing, ensuring that precision-engineered tubes are prepared for use in a variety of sectors. The significance of maintaining accuracy in tube shape cannot be overstated, as it directly impacts the performance and safety of the final products. As technology continues to advance, the landscape of tube straightening is likely to evolve, offering even more innovative solutions to manufacturers. Companies that invest in high-quality tube straightening machines from reputable manufacturers will undoubtedly gain a competitive edge in the marketplace, enabling them to meet the growing demands of their industries with confidence.

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Welding, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.NewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Manufacturing, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Steel Pipe Manufacturing&Industrial EfficiencyNewsJul.29,2025