Conduit Cutting Equipment for Precision and Efficiency in Pipe Processing

Understanding Conduit Cutting Machines The Unsung Heroes of Precision Fabrication

In the realm of manufacturing and construction, precision is paramount. From electrical installations to plumbing, the integrity of the entire system often hinges on the accuracy of the cut materials. Among the array of tools available, conduit cutting machines play a crucial, albeit often overlooked, role in ensuring that pipes and conduits are cut with precision and efficiency.

What is a Conduit Cutting Machine?

A conduit cutting machine is a specialized tool designed to cut conduits, pipes, and tubes made from various materials such as metal, PVC, and other composites. These machines are engineered to deliver clean, straight cuts that are vital for the effective assembly of systems, as even a minuscule error in measurement can lead to significant complications during installation. The design of conduit cutting machines varies, accommodating different diameters and material types, ensuring versatility across various projects.

Types of Conduit Cutting Machines

Conduit cutting machines come in several forms, each catering to specific needs and operational contexts.

1. Manual Cutting Tools The simplest form of conduit cutting, manual tools such as pipe cutters, saws, and hacksaws, are still in use today. They require skilled operators who can achieve precision through careful measurement and technique.

2. Electric Pipe Cutters These machines make the cutting process faster and require less manual effort. Electric cutters often come with adjustable settings to cater to different materials and thicknesses, ensuring versatility while maintaining precision.

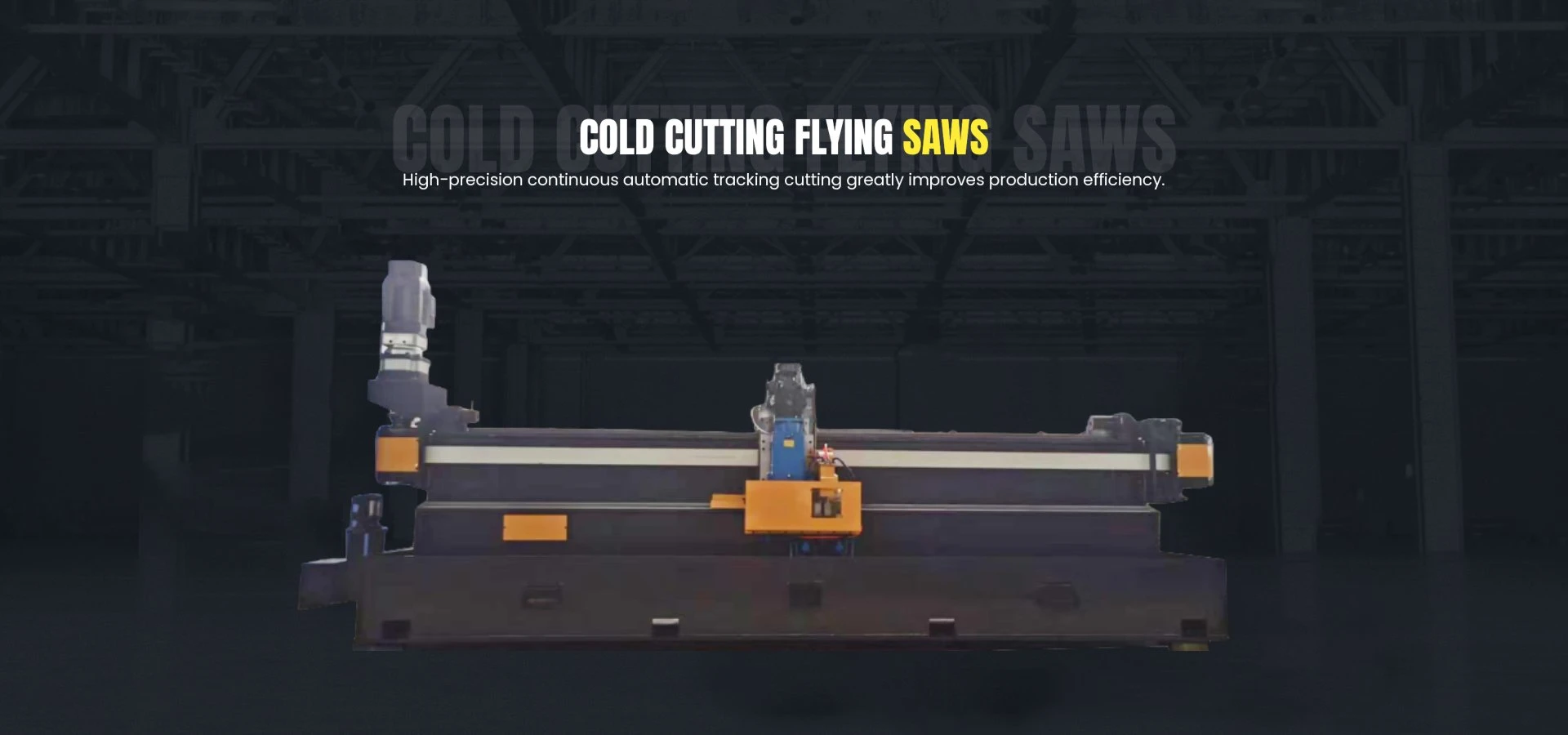

3. Automated Cutting Machines For larger manufacturing operations, automated conduit cutting machines provide high-speed precision cutting. These systems can be integrated with CNC (Computer Numerical Control) technology, allowing for exceptionally accurate cuts according to pre-programmed specifications. This type of machine is particularly beneficial in large shops where mass production of cut conduits is necessary.

Benefits of Using Conduit Cutting Machines

conduit cutting machine

Using conduit cutting machines offers numerous benefits for construction and manufacturing operations. Key advantages include

- Precision and Consistency One of the most significant advantages of using these machines is the high level of precision they provide. Automated systems, in particular, ensure that every cut is consistent, minimizing the risk of human error.

- Increased Efficiency Time is a critical factor in the construction and manufacturing industries. Conduit cutting machines significantly reduce the time required for cutting conduits, allowing teams to focus on other important aspects of their projects.

- Safety Manual cutting tools can pose a safety risk, particularly for inexperienced operators. Specialized cutting machines reduce the physical force required to make cuts, ultimately enhancing workplace safety.

- Versatility Modern conduit cutting machines can handle various materials and sizes, making them suitable for diverse applications ranging from electrical work to plumbing.

Choosing the Right Conduit Cutting Machine

Selecting the appropriate conduit cutting machine depends on several factors, including the types of materials being cut, the volume of work, and the desired level of precision. Organizations must consider their specific needs and budget, as well as the long-term benefits of investing in a quality machine.

For smaller operations, a manual cutter or a simple electric model may suffice. However, larger manufacturers or contractors frequently tackling high-volume tasks might require a sophisticated automated solution. Researching the features, capabilities, and reviews of various models can help ensure the right choice is made.

Conclusion

Conduit cutting machines are the unsung heroes of many projects, providing the precision and efficiency necessary to ensure that conduits and pipes fit securely and correctly. As technology evolves, these machines continue to improve, offering increased capabilities and ease of use. Investing in the right conduit cutting machine can significantly impact productivity and accuracy, ultimately leading to successful outcomes across various applications in construction and manufacturing. Whether through manual or automated methods, these machines are an essential part of the fabrication toolkit, helping professionals shape the future one cut at a time.

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.NewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Manufacturing, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Steel Pipe Manufacturing&Industrial EfficiencyNewsJul.29,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Steel Pipe Manufacturing&Industrial EfficiencyNewsJul.29,2025