line pipe manufacturer

The Future of Line Pipe Manufacturing

Line pipes play a crucial role in the global energy and utilities infrastructure, transporting oil, gas, and water over long distances. The line pipe manufacturer industry has evolved dramatically over the years, adapting to new technologies, sustainability demands, and market trends. As one of the cornerstones of modern infrastructure, it's worth exploring the advancements and future directions of line pipe manufacturing.

Understanding Line Pipes

Line pipes are high-strength pipes typically made of carbon steel, designed to withstand high pressures and harsh environmental conditions. They are extensively used in various sectors, including oil and gas, water distribution, and chemical industries. The manufacturing of these pipes requires not only advanced technology but also strict adherence to safety and quality standards, ensuring that they can operate efficiently under extreme conditions.

Advancements in Manufacturing Technology

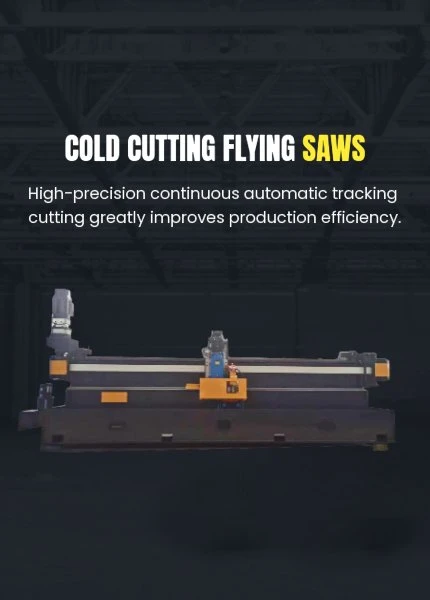

The advent of modern technology has brought significant changes to the line pipe manufacturing process. Advanced manufacturing techniques, such as automation and the use of sophisticated machinery, have increased production efficiency while minimizing human error. For instance, the introduction of Computer Numerical Control (CNC) systems allows for precise cutting and shaping of pipes, ensuring uniformity and quality.

Additionally, the use of non-destructive testing methods, such as ultrasonic and radiographic testing, has enabled manufacturers to inspect pipes for defects without compromising their integrity. This ensures that any flaws are identified early in the production process, reducing the risk of failures in the field.

Sustainability in Pipe Manufacturing

As the world becomes more environmentally conscious, line pipe manufacturers are also focusing on sustainability. The energy industry is under pressure to reduce greenhouse gas emissions, and manufacturers are exploring ways to minimize their environmental footprint. This includes utilizing recycled materials, improving energy efficiency in manufacturing processes, and developing new materials that require less energy to produce.

line pipe manufacturer

One notable trend is the push towards using high-strength, lightweight materials that require less energy to transport and install. Companies are investing in research and development to create composite pipes that combine the strength of traditional materials with lighter alternatives, significantly reducing transportation costs and overall emissions.

Market Trends and Challenges

The global demand for energy continues to rise, driven by population growth and industrialization in developing countries. This trend is reflected in the increasing need for line pipes to support various infrastructure projects. However, the industry is not without its challenges. Fluctuating raw material prices, regulatory changes, and geopolitical factors can all impact the production and distribution of line pipes.

Moreover, the increasing emphasis on renewable energy sources leads to a shift in the types of materials and technologies used in line pipe manufacturing. Manufacturers must stay ahead of market trends by continually innovating and adapting to meet the evolving needs of consumers and regulatory agencies.

The Future Outlook

Looking ahead, the future of line pipe manufacturing appears promising. As technologies continue to advance, manufacturers will likely embrace emerging trends such as artificial intelligence and the Internet of Things (IoT) to optimize production processes and enhance supply chain management.

Furthermore, collaborations between manufacturers, energy companies, and governmental agencies will be essential in shaping the industry's future. By working together, stakeholders can develop standard practices that prioritize safety, efficiency, and environmental sustainability.

In conclusion, the line pipe manufacturer industry is at a pivotal stage, balancing the need for robust infrastructure with the demands of sustainability and innovation. By leveraging technology and embracing new materials and practices, manufacturers can position themselves to meet the challenges of the future, ensuring the continued safe and efficient transport of essential resources across the globe. As the industry evolves, it will undoubtedly play a key role in supporting the energy transition, making it an exciting field to watch in the coming years.

-

High Frequency Straight Seam Welded Pipe Production Line|BzZhou Xinghua|Precision Welding&EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line - BzZhou Xinghua|Precision Engineering&EfficiencyNewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.NewsJul.30,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Manufacturing, High EfficiencyNewsJul.30,2025

-

High Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Steel Pipe Manufacturing&Industrial EfficiencyNewsJul.29,2025

-

High-Frequency Straight Seam Welded Pipe Production Line-BzZhou Xinghua Machinery Equipment Manufacturing Co., LTD.|Precision Steel Pipe Manufacturing&Industrial EfficiencyNewsJul.29,2025